Tech Tips – Using Tuff Torq Repair Kits

Tips for Tuff Torq Repair Kits

(K46, K57, K574, T40 MODELS)

The Tuff Torq service team has put together this summary outline procedure for using our Tuff Torq repair kits to service your drive system. These are just tips and should not be considered a complete repair guide for every issue you might have. All repairs and maintenance of our drive systems should be performed by a professional service technician. If you have any questions or need specific help for your issue, feel free to contact our service team at (866) 572-3441 or through the website by clicking here.

Receive the correct repair kit

- First, clean the outside debris from the unit.

- Be sure to locate the proper serial number of the TTC unit (Located on the barcode sticker).

Removing unit for repair

- After you have received your parts, please inspect the parts. Note the mating surfaces must be smooth and clean.

- Repair Kits generally include the center case, pump cylinder block, motor cylinder block, filter, o-rings, seals, and sealant. When repairing your unit, it may not be necessary to use all o-rings, and seals.

- Drain the oil from the unit. (DO NOT reuse the oil) Remove the flat rubber seal cap located under the fan to drain the oil. No need to remove the vent valve.

- Place the unit on your workbench with the fan facing down.

Opening unit an performing repair

- Remove the case bolts and remove the lower housing.

- Scrape the sealant from both the upper and lower cover. Be careful not to damage the sealing surface while scraping the housings. (Remove all sealant completely)

- Now is the time to use the drawing and parts list from TTC’s website to identify everything inside the unit www.tufftorqservices.com.

- Clean and flush the unit. Improper cleaning of the unit could result in a premature failure or void the parts warranty. You can clean internal parts with standard brake cleaner.

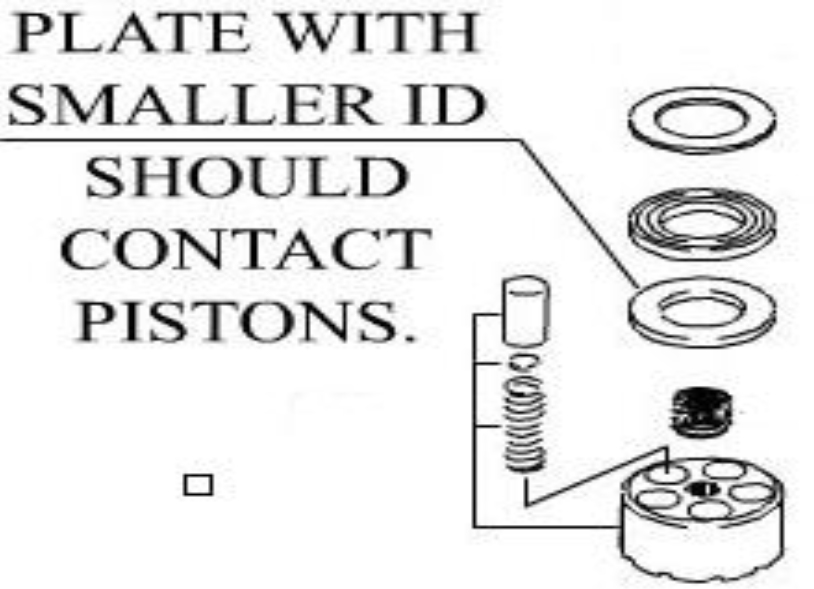

- If you choose to inspect any parts make sure these parts are placed back into the proper orientation. (Ex. If you remove a bearing or a plate make sure that it is placed back into the proper position. Plate with smaller ID (INSIDE DIAMETER) should contact Pistons.) The notes are listed on most drawings so be sure to follow these tips properly. (see Fig#1)

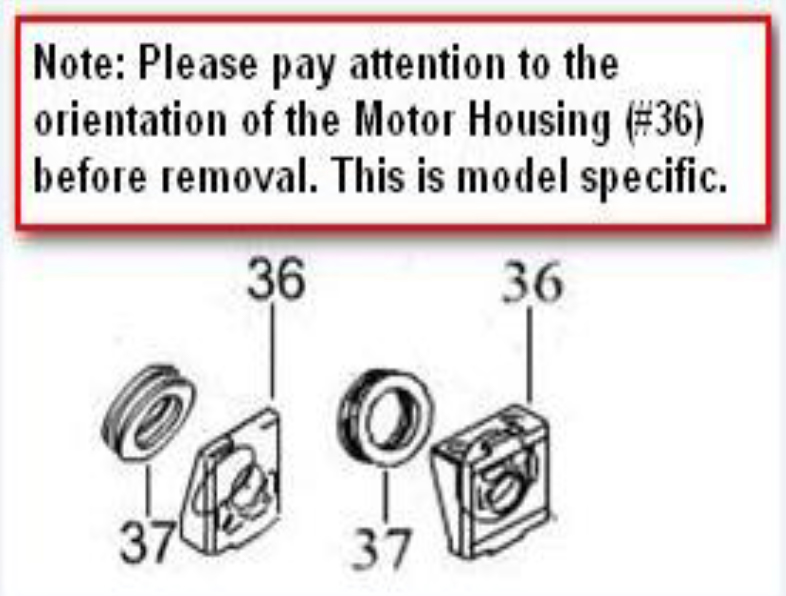

- Note the original position of the Motor Housing. (see Fig.#2)

- Once you are ready to install the parts be sure to coat the mating surfaces with oil. This will help lubricate the contact surfaces.

Re-assembly of unit

- Make sure to re-install the bypass pin and washer from the original center case and motor cylinder block. You can use a light amount of automotive grease or Vaseline to keep these two parts in position while putting the parts back in.

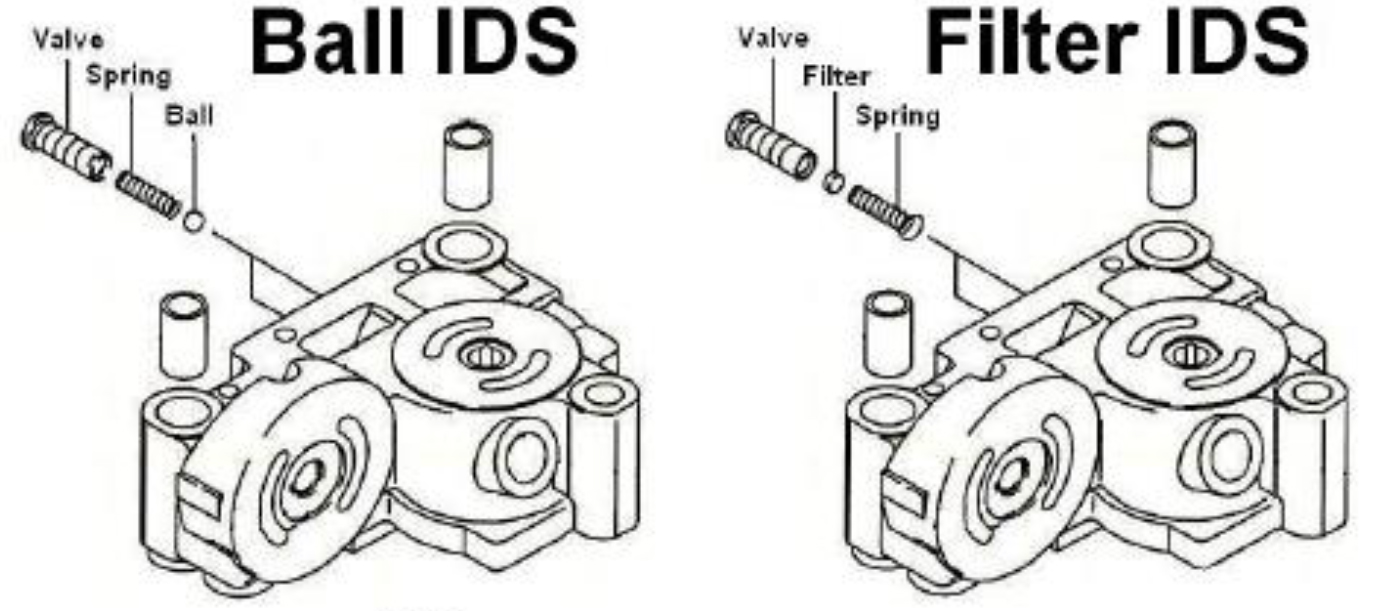

- If the unit has IDS valves, be sure to note the correct position of the ball or the filter compared to the drawing (see Fig.#3).

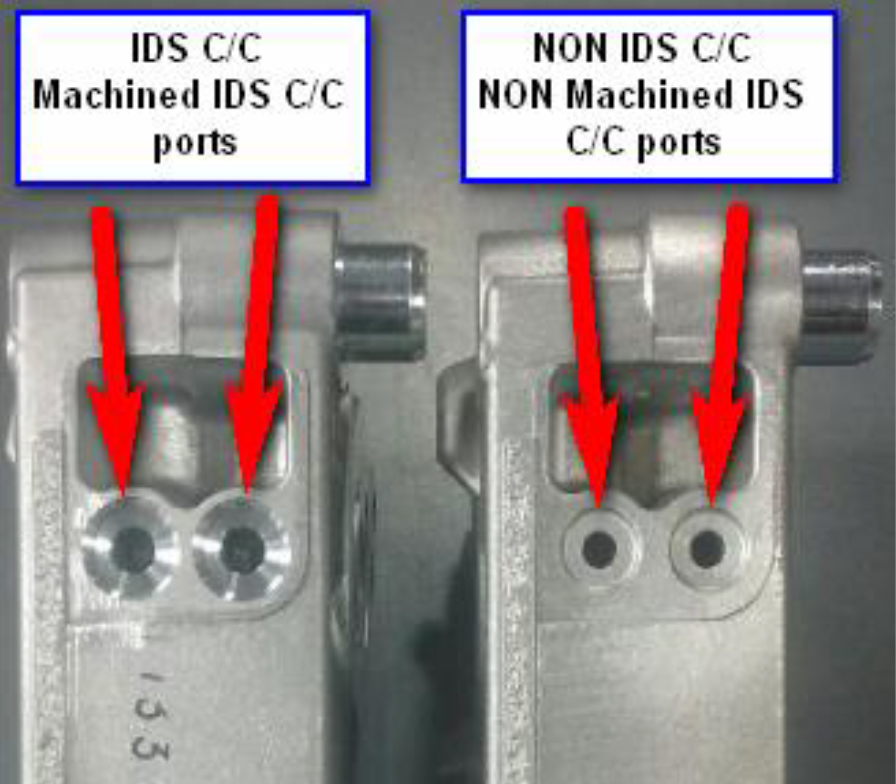

- New center cases will have pilot holes for the IDS system. See figure 4 to understand the difference between IDS and non-IDS units. The non-IDS unit will not have finished machining at the pilot holes. This is simply in the case mold design of the new center-case and does not impact the performance of your unit.

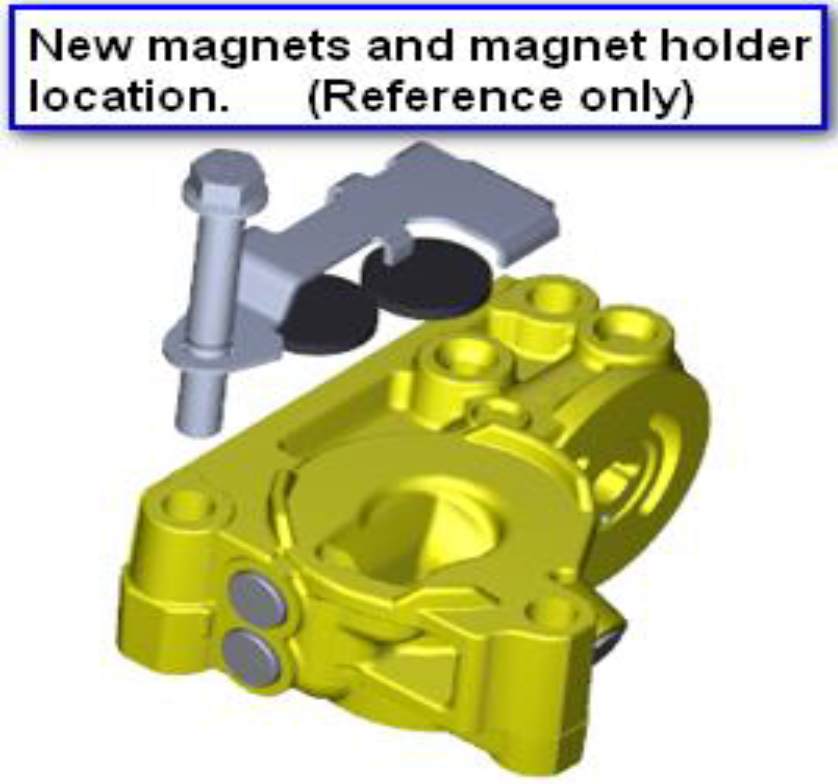

- New style magnet holder and two magnets (see Fig.#5 on back) for proper orientation.

- After re-installation, check to see if everything will rotate freely.

- It is critical that the operator maintains proper oil levels at all times.

- Maintain oil level at 20~25 mm (3/4”~1”) below the lip of (black cap) the filling port.

- Always check oil level when the oil temperature is at room temperature (20C or 68 F).

- When replacing oil in your unit, Tuff Torq Corporation recommends using Tuff Torq Tuff Tech™ hydrostatic drive fluid when rebuilding Tuff Torq transaxles. (DO NOT use ATF Automatic Trans Fluid)

Share This Article

Good afternoon I have a John Deere la 145 that naves very slow .I took tans mission. Out come to conclusion it is pump or motor.. do you sell replacement parts

I own a Simplicity Prestige 4wd unit with the KXH10 front axle and K664 Rear Transmission. The tractor has excellent forward speed, but reverse seems slow, doesnt seem to be near the 3mph rated speed. Is this normal for this unit? Reverse does not seem weak, just slow. Definitly slower on a steep incline backing up(20 degree slope or more), but seems slow even in flat ground. Shoukd the hydro slow down that much on a hill in reverse? Forwards seems fine even on steep slope. I have checked that all the linkage is allowing full travel. Have even disconnected the stabilzer on the rear to rule that out. Hydro recovery tank is filled so it covers the tube that runs to the front axle also. Very recent service with a new filter and synthetic 5w50 oil. System was bled with air multiole times to also rule it out. Tires are correct orginal size and are properly inflated. This is all on days that are arounf 70 degrees farenheit. Thank you in advance for any answer you may have.

need repair kit # for 66l-001861 trans. simplicity # 1721952 . also need name & number for dist. for parts

Hi looking for repair kit for tuff Tork transmission 768T2024011 serial no40J-1006117 other no JDPP MIA10910.

I am in Australia can you tell me if this is available and the cost to get it in Australia. This transmission was installed in John Deere L110. Hoping you can help.

Thanking You

Eddy

sir i need rebuild kit for T40A-john deere-768t202400 could i get kit number and price thank you ron

Hi, I have a tuff torq 7a646084230 sn:57k 0002247 that is leaking around the bottom of the case. Can you please help be find a replacement seal for this? Thanks

I have a westwood s1600 with a k46, 1a6460-84251 is the serial number on the casing. I need a rear left hand axle and seal but am having trouble sourcing one. The unit differs from anything i can find in the uk. The axle has a bush that is fixed on the shaft. I hope you can piont me in the right direction regarding axle and sel part numbers and suppliers, many thanks, Jason.

Looking for a rebuild kit for a simplicity model 2691178 transmission

It won’t move forward or revu

I have a 3/4 year old K46 fitted to a Honda HF241792019/2020. The IDS valves have only springs and NO filters or balls . Can you confirm if this is normal . The label is missing on the unit .

I have a JD X485 with a K92 transaxle that needs replaced/rebuilt. Do you know of anyone in eastern PA that will rebuild the unit?

Need repair / rebuild kit —- TRANSAXLE(K46AW)22″FS. (Internal parts not available) HUS-532448354

Need rebuild kit for 7A646084120 46BE0016800. JDPP. AM 134584

Looking for rebuild kit for due10E do you have one ?? If so what’s the price.

repair kit for the Z242E zero turn mower ?

I have a k46 7a646084180 s/n 46bt0199538.

Please send me the correct rebuild kit number and quote.

Regards,

I am looking for a splined input shaft for a John Deere 1565 hydro unit but cannot cross reference it can you help

I have lx188 wishing to change oil, filter service unit on a Tuff Torq 110673 unit, can you help with available and cost please thanks Russell

I have a 1994 John Deere lx188. I do not have a bar code. the number below the tuff torque logo is 018042. I want to order a rebuild kit

for this K61 transaxle.

Can the Tuff Torq, Differential Lock Kit, 1A632087360 be installed on any k46.? Where can I find installation instructions?

Where may I be able to acquire a seal kit for my K57R Sears garden tractor and what is the part number for this part. I am losing power when I push the forward and reverse peddles and need to replace the filter. I understand that this kit has everything I may need to do the job. I live in Cambridge, Ontario, Canada. Thanks

Need a rebuild kit for a JD LA145 transmission. These are the numbers I got of the tuff torq label: tuff torq 768t2024011 s/n 40j-0390129

jdpp pn: mia10910. please recommend proper rebuild kit.

Hi

Do you have a replacement left hand side rear axel for a John Deere 300R the marking on the trans gearbox is

7A646084141 SN 46BD0010585

If so how much are they and where can I order them?

Can I replace my mia10910 with a jdpp am134584 transaxle by tuff torq

Hi, My LT180 JD looses drive when hot. Is there a hydrostatic repair kit (including oil) available for a k46C rear drive unit or do i need to order a replacement asm? S/N = 46C-0052675 john deere pn AM 130330. Can you please advise new rear drive unit & service kit pns and if parts can be purchased directly from tuff torq and shipped to Australia? John deer parts catalogue references 7A6460-24021 against the JD pn AM 130330, not sure if this is the Tuff torq rear axle pn?

if I failed to pay attention to orientation of motor housing, (part 36 ) is there a way to know for sure?

Hello ,

I have a John Deere 14.5/38 Sabre riding mower. It has a Tuff Torque 51a . The right rear axle seal was leaking. I obtained the part and found the time to replace it. It seems to me that the axle has to much up/down play causing the seal to leak. In my search it seems that the 51 doesn’t have an Axle bearing/ bushing.? Can you provide any insight with this?

Thank you

Need rebuild kit for PN#:768T2024000 SN#40A-0006369

did the trans torq in 2004 L100 johndeere have grease or oil in it. No fill plug , I had to put a wheel seal in the unit. but cant find plug to ck the level

Looking for small bevel gear set for k51B. Also filler plug and breather plug. Thanks

I HAVE A EQUIPMENT WITH TUFF TORQ 7A646084510 S/N: 57AE0001767. I NEED A REPAIR KIT, HIS TRACTION HAS DECREASE. I WOULD LIKE TO KNOW THE REPAIR KIT CODE AND VALUE. DELIVERY IN BRAZIL. I WAIT FOR YOUR RETURN, THANK YOU.

Hello!

We have a ride-on mower Partner 13-85R with Tuff Torq 7A6460224070 S/N: 46H-0084285, P/N: 506 9868-01. We need a correct repair kit, because the traction of the device has decreased. Is it still available and at what price? The repair kit should be delivered to Finland.

Need rebuild kit for

7A646084591

SN 46DM0588109

Please send kit number and dealer info.

Where in Canada I get rebuild kit for K46bt?

hi do u have a place to buy parts for a k46 transmission in the UK ?

Rebuild kit for hydrostatic pumps

Husqvarna rz4623

i have a toro grand stand 15567

hello could you please give me part.no for repair kit for mia12745 transmission

What is the correct overhaul kit for 7A646084161

Good info have u a kit for John Deere LX188 lawn mover

7a646084180

46bt0114069

Is there a rebuild kit available for this that will work? Thanks

need rebuild kit for right trans axle

787Q0827010 S/N R0026046

I have a K46C S/N: 46C-0056774, can you please provide the correct rebuild kit to order and cost.

Im looking for a complete k46 transmission rebuild kit for a JD L120 lawnmower.

Hello, I have a l110 with the k46v. The serial number is 46V0073059. Could you please tell me the correct kit to order and cost. Thank you

Purchased rebuild kit for k58. Wanting to know the purpose of the bypass pin and what keeps the pin from fall thru the case?

Mi tractor es L120 transmission k46ac donde puedo conseguir los resortes que van en el center casé y los balines.

My mower was pushed up in garage about 5ft during the winter without pulling relief valve. The mower will not move under engine power. This is a new transmission bought last summer. What could have gone wrong?

Which kit for the jd la175 and how much is it.thank you.

I want to be clear about the fill port on my JD 125 automatic lawn tractor T 40 transmission. Is it the metal cap forward or the rubber cap at the rear? Also, low vis or high vis oil?

I wanted to see about getting a rebuild kit for my transaxle. It’s a k46., It’s on an ’05 John Deere L120 GXL120A082485.

The bar code sticker that y’all put on the axle, the numbers aren’t readable except maybe the first four or five. I can send a picture of what’s there if you scan the bars maybe. I pulled it out a couple of years ago and refilled it with synthetic 5w50 I think it was and it helped the slipping some. I did it again this past spring and it helped again but it’s beyond that now. How can I identify for sure which model it is? It’s screeching bad and reverse will work a little. Will the rebuild kit get me another 2-3 years out of it? It’s only got about 500 hours on it.

When I take out the ETC Diff Comp I can turn it by hand in both directions and both sides when I place the axle in it. Does this mean the unit is worn?

Hello, I have K46-1A6460-84300#3 on the housing of my transmission. I need a rebuilt kit. What do I need and do you have the number of the required kit for this repair.

good morning, I’m matteo from Italy, I would kindly like to know the repair kit number for tuff torq transmission 787Q0324100 s / n 574D- 005282

and where to take it to buy

Thanks greedtings

Tuff Torq Rep., I have a John Deere LA135. The transmission is having issues going up hills after it gets hot, about 15 mins. of running, but it works great on flat land. Every two years I have removed the transmission and changed the oil in the off season using Mobil One Full Synthetic 15W-50 oil each time. After a lot of online research, I understand going up hills will generate a lot of heat on the transmission, resulting in this issue that I’m having. I believe that my best option, because I do like my John Deere, is to rebuild the transmission with the “Tuff Torq repair kit”. The following are the numbers on the transmission:

768T202411 – 40J-0613329 JDPP PH MIA10910

I live in Knoxville, TN and go the Johnson City, TN often to see family. So my question are:

> What is the rebuilt kit part number that I need?

> What is the cost of the kit?

> What is my best and lowest cost in shipping or if available can I pick it up?

> Would using Amazon prime be a good way to go about ordering it?

Hi , I’m after a repair kit for my Tuff Torq transaxle , as it losers drive when it gets hot and struggles to gp up hill. I have replaced oil etc and it’s time for a rebuild. Part numbers as follows.

Tiff Tora 7A64084322

S/N 46CR0192489

HOP 501051401

K46CR.

Hi, I’m after a seal service kit for my Tuff Torq Differential, the kit I’m after contains replacementparts like, Axel seals & other main seals, gasket sealant, hydraulic oil etc.

My Part numbers as follows:

7A646084321

S/N 46CR0086889

Thankyou

Tuff Torq : 7A646084161 / s.n. 46BN0085342

I need a axel repair kit. What is the correct part number? Thanks

Please send me the Tuff Torq Repait Kit part number for 787T0124000

Dear Sirs,

What is the model of the repair kit for the Tuff Torq transmission part number 787T0124000? Please let me know in order to order the kit.. Thank you

Hello, I have a Westwood V20-50 with a sluggish reverse. The numbers I got off it were:

TUFF TORQ KB20 S/N: 820-0002217

COUNTAX PIN: 478000400

Is there a rebuild kit for this model?

i purchased an axle kit for the k46. Replaced the broken axle first (the longer one) installing the axle clip and the thicker spacer . Same for the shorter shaft except i can”t get the thicker spacer clip in. Any suggestions

I have a Husqvarna LGT2654 with 800 hrs. Never had any problems until frame broke. I mowed 10 acres, pulled a plugged, sprayer and maintenance/yard wagon. Recently repaired the frame and mowed 10 hours before the right axle broke. Is it worth repair? What trans kit and axle(s) do I need. K46 AW (406206).

I have John deere with k46 be transaxle, im looking for rebuild kit

I have a Toro 267HE, Mod.: 78268, Serial nr.: 8900140, Kohler engine: 128000-7480, Tuff Torq K61,

Hydrostatic Transaxle.

I need:

1. The fan/ventilator over the Hydrostatic Transaxle.

2. The oil filter inside the Hydrostatic Transaxle. Diam 70mm x hight 25mm

3. The drive belt between the Kohler motor and the Hydrostatic Transaxle

I do not know the length of the drive belt, but I can take the old one away and measure it if needed.

4. The sealing compound to seal between the upper and the lower part of Hydrostatic Transaxle.

The Toro representatives in Sweden, do not have any parts for that old machine.

They asked me to contact the representatives in the USA

I found this page and hope to find the parts missing.

Do you have a complete price list with photos and numbers of all spare parts?

Please send it to my email:

kontorsstolen@hotmail.com

Have a nice day!

….and Take Care!

JoJo

Do you have an oil change and seal kit for a John Deer T40 K46 also an axle kit. Both of the axle keyways are rolled. Mower has 1350+ hrs.

Rebuild kit John deer tuff torq 787q0824001 sn 7d-l0168544

We have a John Deere Z535M with the left drive inoperable. The transaxle is 787Q0824001, sn 7D-L0111605. Is a rebuild kit for this unit available?

Do you have a repair kit for an AM131580 hydrostatic drive from a John Deere L120, around 2003 or so vintage? If so, what cost?

Thanks

Do you have a repair kit/ rebuild kit for a 7A646084320 s/n K46CR0004105 HOP PN 417213 and what is the cost. Had it a while now, and loses power after it heats up, changed oil but still same situation, now I have to open it up and clean and rebuild the unit, also could use a new cap for under the fan small cracks have appeared on top.

Hi! I have a K574 transmission with 4WD. My problem is that only the front wheels drive are working. Have opened the transmission without finding any failure inside. Have replaced the filter and the bearings before assembling it together again. Didn’t make any difference. Do you have any ideas of what the problem might be?

I have a K71A hydro that will not move and makes a hi pitched noise. What are common failure modes for K71As and is there a rebuild kit or manufactured unit I can purchase?Thanks, Jess P.S JD GX 325 I’ve had it 18 yrs and never serviced the transaxle.. (insert sad face emoji here).

Do you have a repair kit for 57af0009656 and at what cost

Thank you

I have an earlier model tuff torq transaxle in a John Deere riding mower LX178 and the only number I can find on it is on the top (061307) Can I still get a rebuilt kit for this unit. Couldn’t find one on the site.

Thanks,

Galen

I have a 57a-0012914

Im not seeing a seal kit for this model. Do you carry seal kits for Simplicity Broadmoor?

Do you have a rebuild kit for JD LA-150?

Leaking seals KT574

I have a LGT 2654 husqvarna with a K57 trans axle oil leaked out during last mowing. Didn’t realize it was the transaxle at that time. Now, mower will go forward but is very unhappy about going in reverse. Sometimes will not go in reverse at all. I don’t exactly know where the leak is located. Is this a common problem? What can I do to repair/fix. Is it shot?

Do you have a rebuild kit for k46 mia10910

Do you have a repair kit for John Deere Zero Turn Z525?

Good Morning.

I bought a New Holland lawn mower (by Tramontina), which uses Tuff Torq transmission 7a646084510. This transmission was opened and reassembled by another mechanic, and it is operating in reverse, I move to go forward and it goes backwards fast, I move to go backwards and it goes forward slowly.

Regards Abel Saggioratto

I have a Husqvarna LGT 2654 with a Tuff Torq K46 Trans. Here are numbers off the Bar code. 7A74609 (8-5-6 ?) 4990 46aw001994 PN 406206

I need the Part Number and price for a Left axle Kit with necessary parts to complete the repair.

Thanks,

Larry Ball

I have a JD L130A mfg in 2002, model GXL130A013939, but the transmission label is missing.

How do I know which model trans I have?

I need a seal kit but the barcode sticker is missing. Is there another way to figure out what kit I need? This Tuff Torq is out of a 2001 JD GT235, other websites state it is a K71 but I want to make sure I do this correctly.

I have this trans below 7A646024390 Ser. 46ac0246609 JDPP P/NAM131580

When I step on the gas and I am going forward it appears at some points to make a clunk as the clock happens forward movement momentarily stops and then goes again. It seems to only happen when the transmission is stressed a bit by either going around the corner or if the front tire it’s a hole during a turn. Would you have any idea when I might need?

7A646024390 Ser. 46ac0246609 JDPP P/NAM131580

Looking for a differential gear kit on here but everything looks like it’s out of stock.

I am looking for a Rebuild Kit for a K46AC S/N: 46AC0076920 JDPP P/N: AM131580

Is there one available?

Hi there ,I am experiencing a screeching sound when using my Castlegarden mower which is fitted with a K46 transaxle, there are 370 hrs on it from new, I inspected the gears and differential all appear in good shape, works fine but noisy, any pointers or suggestions please.

Hello

I have a Tuff Torq axle model 7A646084130 , s# 46BC0027759 in my JD X300 Mower. The input shaft pulley has stripped out. I was going to replace the pulley, shaft and seal. What are the part numbers for these parts?

I have a Husqvarna model HQYT48DXLS lawn tractor with a K46 (model 960430226) transmission with S/N 46CR0197848 that is slipping when going up hill. What modification would be required to change the present K46 transmission to the K66? Would you furnish mounting info to determine if this is a possibility.

Would it be possible to purchase the K66 transmission thru you if modification is feasible?

The present mower is only 3.5 years old so any help will be appreciated.

Thank you, Mike

Hello, I have an older K664 and 4WD Transaxle + Aux Ports.

It came with a SNAPPER/SIMPLICITY RD2140 4WD +SERVO. Its at least 10 Years Old, unfortunately, the Sticker with the ID is gone.

I want to Purchase a full Repair kit including the AuxGearPumpHousing (bad thread on one port) and Valves! Can you provide the TuffTorq Codes for it? I am from Germany and I tried alot to get the right parts. Help would be appreciated!

Have a good Day.

Sebastian

I have John Deere, L-130, with a Tuff Torq Model K46AC, S/N: 46AC0102988, OEM#: AM131580. Where can I get the Part number for a rebuild kit

I have a john deere sabre with a k51 transmission that makes a noise and shifts slow until it warms up. I replace the upper pulley, shaft and oil, any suggestions?

I need a full rebuild kit for a 7A646084181 S/N 46BT0654378 transaxle. I find that the main parts are listed as no longer available but yet I can buy an entire new transaxle with the same ID numbers. Why can I not buy parts for an axle that is still being produced?

Do your new k46c transaxle ship with oil and a fan included with your order or do I have to buy those separately? Thanks

I need a rebuild kit for 7A6460-24021 S/N 46C-0011739

I need a rebuild kit for a 7A646084100 S/N 468A0262983

I have a John Deere LX188 with a leaking axle seal should I remove the entire trans out and put on my bench? next question when I remove the lower cover are there any parts that will be moved out of place when the axle comes out to install the new seal?

Hello, I’m looking for a rebuild kit for a transaxle with the following numbers Tuff Torq 7A646084181 S/N 46BT1300127

Hi

I am after an expansion tank for a Tufftorq 787Q0324010 S/N: 574A-085172

I have a 2001 john deere gator 6×4 with a tuff torq transaxle serial # 117982. what transaxle is this and do you offer a rebuild kit for it ? part # please if you do so i can get it ordered.

je voudrait savoir si on peux acheter chez vous et si vous accepter paypal

john deere l 118 transmission 40a-0181380 savoir si il a un kit pome et moteur

je voudrait savoir si il y a un kit pour la trammsmission torq768t2024001 40a-0181380

Where do I get parts for a tuff torq k51a gohn deere sabre 1642

I have a husqvarna LTH1797. When going forward it is very slow but somethings takes off quickly for just a few yards. The reverse is all good and operates properly. Would you be able to tell me what could be wrong with the drive unit. In forward motion, a person can walk much faster than the machine will . Thank you. Email , 1wnhn2@gmail.com

Not too sure which way the “Jerky Plate” (#54 in parts diag.) is supposed to go back in to the K46 Trans. It is hollowed on on side, solid on the other, has a curved side and a flat side. It fell out and I didn’t see how it was positioned! It sits againts a control arm #52 in parts diag.

Thanks.

Looking for a link to drawings for parts/rebuild kit for a Cub Cadet XT1 Tuff Torque transmission- 7A646084590 S/N 46DM0161335

Thank you.

Do you offer rebuild kits for John Deer MIA10910? TUFF TORQ p/n 68T2024011 s/n 0606005. It is the transmission used in John Deer LA 145 with 48″ deck.

I have a TT K46-BT. After replacing the fuse for the starter I have discovered my mower will no longer move forward or backward. It worked fine prior to replacing the starter fuse. Any ideas on why the mower will no longer move? Thanks.

with K46A trans I read there is a part # for Heat-Treated Steel gears replaces part # 1A646031570 do you have this part and or part #?

.

Hi

I have a TT trans from a John Deere X300R lawn tractor.

Broken left axel.

TT PN: 7A646084141

Serial #: 46BD0041120

Can you tell me what I require to repair please.

Located in Sunshine Coast Queensland Australia.

Regards

kjg

for Pelican Waters Heart

on my deere 46A AM130747

What would be the part # for k57 upgrade kit. I read the charge pump increases durability. I want to upgrade center case / pump shaft/ charge pump…

I gave my trans to a repair shop, and he gave it back to me in a basket, took me a while too figure out what was missing as I put it together.

I noticed in pics after reinstalling I did not see or remember installing spring #1A646099070 under pump. Would trans still work w/o spring? I resurfaced center pump and new motor & pump.

it works but trans looses some power when hot. so I want to replace center case with charge pump next time i pull apart.

I just finished installing my k46A trans and working OK I never liked the speed of this tractor (LTR180) the problem is cannot get to trans mision to clean because of the shoot (center rear discharge) I’ve read that the k66 trans would not fit my tractor, but can I fit the k66- pump, motor, wash plate, shaft, charge pump… into the k46 trans?

I’m working on my K46BT, serial number 46BT1060678. TT # 7A646084181. I thought I had taken pictures of everything before I disassembled everything.. Well, I must not of and I can’t remember the orientation of the motor drive block. I can’t remember if it was thick side up or thin side up. Any help would be appreciated.

HI I’m looking for a tough talk diff rebuild kit please

I am looking for a rebuild kit for a k57 on a 2007 simplicity Broadmoor , do you have one available and a part number?

Do you have a rebuild kit for JD LA-130?

I had a local guy change the oil on my K46/T40 (John Deere LA135) hydro this spring. Ever since I got it back it rides really rough when cold and goes really slow in reverse. After it warms up it starts to run much smoother, and it actually speeds up in reverse.

Have a husqvarna LT 2654 with k46. 46bn0044004, need correct hydro diagram. Thanks

I am looking for the seal kit for 7a646084100. Can you recommend which kit to purchase?

I have a Husqvarna LGT2554 with the K46 with the S/N: 46AW0002255. I can’t find the rebuild kit on the site, could you help? Thanks

I have a z425 54 inch John Deere need left side transmission repair kit thanks

-

I need an RH Transmission repair kit for Z 425 54in John Deere, Thanks.

What overhaul kit suits k46. S/n 40J-0833205 please ?

What is the repair kit # for a 768T2024011 trans axle transmission

I have a John Deere L118 maybe 2004, with Tuff Torq 7A646024380 SN 46V-0278552

iv’e taken it out because it was getting weak pulling up inclines, especially when hot. What are my options as to rebuilding this unit, kits or any upgrades? and estimate for cost of options. This unit has never been worked on as I have owned it since new and I will be doing the work myself . Thanks for your advice

I have a K51B.can I replace the bypass shaft seal ( o-ring ) from the top without disassembly of the unit.so meaning when I remove the pin and lever will the shaft fall into the gear case?

I have a 7A646084020. SN57R0019816. HOP pn 437814. I can go forward and back wards at low speed but when I try to go faster it lurches and makes a loud clicking noise, I think we overloaded the pull behind trailer and broke some thing,,,do you have a rebuild kit for this unit, thank you in advance

Hi, I have a K574 (787Q0323030 S/N 574C-003694) & HFWD when warm it is very slow going forward and will not go up an incline, strangely in reverse it is fine. I suspect it needs a rebuild but not sure because it’s okay going in reverse. Can you advise?

I have a tuff Torq 7681202401 which has just started to have trouble driving. I notice the rubber cap under the fan is leaking (Perished). First thoughts were to replace the cap and the oil. S/N 40J-0833205. Having trouble finding a replacement cap. Could you please advise.. ? Thanks.

I have a Tuff Torq 7A646024021 s/n 46C-0124770 and am looking for a rebuild kit part number to order. Also how do I find out what parts are included in the kit?

K46 Rebuild Kit

I have a K46 in a 2013 John Deere with 140 hours on it that has broken springs under three of the 5 pistons. I took a fourth spring in my fingers and it snapped like a pretzel would if you tried to bend it. There is no visible scoring or discoloration that would indicate overheating and makes me wonder if there was a bad batch of springs from your supplier. How do I order all 10 replacement springs and what are their p/ns? My axle info is Model: 768T2024011 S/N: 40J-1320433

I have a John Deere Lt160 with a Tuff Torq K46C Serial # 46C-0077400 Transmission with 2000 hours on it. I all of a sudden lost all drive. The belt and pulley on top of the transmission are good. It makes no noise and you can push the tractor freely like you have disengaged the transmission. Also the pedals feel soft.

Hello I just got a riding mower with a 46BA hydrostatic, the plunger in the back to roll freely was in the locked position, once i got it home I unlocked the plunger to roll freely, after I started the mower, I engaged the plunger the mower did not move, took the unit off drained fluid, was not full, took the cover off, didn’t find anything broken or out of place! I seems the plunger or mechanism to to lock the wheels from free roll may be the problem.

I can’t find any references or picks to show that part!

Hello have k46 BE once warms up reverse is slow and won’t go over 2×1 hump into shed , forward is much better no problems after 5w50, taken apart second time to check pump and motor little chater on aluminum face but found ids with filter seized , can this be reducing pressure or loss of pressure, will polish the pump and motor contac on center case pump and motor no scores or wear visable

thanks

joe

Looking for parts diagram for K574 4wd, lost all drive ?

Hi,

I have a Husqvarna 2654 riding mower with a Tuff Torq 7A646084161, SNBN8068484 transmission. I need to replace the broken left axle… I cant find a part number for the new left axle in your parts search. Can you help?

I have a John Deere L130 automatic and I need to either replace or rebuild my k46 hydrostatic transaxle and was just wondering how much your rebuild kits are and I also need a new fan and plug where the magnet goes.

I have a JD LA 165 with a K46 Tufftorq. The barcode for proper parts ID is gone. Is there another way to finding this info?

I have a craftsman riding lawnmower with the k46bt tuff torq hydrostatic drive the shifter lever seems to be not in gaging and it falls out of the hole was just woundering what part i need to fix problems

Hi, I have a JD D140 replaced the transmission oil tractor will barley move. I found the fan on the transmission will not move. Not wishing to replace the entire transmission and hopefully don’t need the $450.00 plus repair kit.

Thanks

I am looking for a rebuild kit for a K51. The S/N tag on the transaxle is missing, but it is from a Late 2001 Simplicity Broadmoor 16H Model 1693840, Simplicity Transaxle P/N 1720876SM.

And is that the fluid that goes in a k62?

How do I order the tuff torq tuff tech hydrostatic drive fluid?

I have a John Deere Z425 with a model DUP10E sn#10e070213 is there a rebuild kit for this ? It locked up?

trans not operational; removed from mower, gears look great, what do I look for that rendered this unit to be non-operational??

HELLO

i bought a used John Deere zero turn Z525E , 200 hours , mowing climbing a slope the right hydro static transmission failed , and since then having great difficulty repairing it , the only way i found is to buy a new transmission which costs $950 and with installation and taxes will cost me $1400. it is a very high price to fix a like new lawn mower , any help any suggestions is very appreciated

I bought a John Deere L118 unlimited ran good when I bought it I got it home an my yard has a slope an it started an mowed fine Then it was sluggish on the slope an stopped pulling then just started to sweak like a power steering pump on a car would when it’s low so I had a guy look at it he said changing the fluid would help so I got the stuff an he changed it an within minutes of mowing it started the same thing new belts an new fluid. Is there a tranny that could replace mine or what the cheapest to do thanks in advance

Hello, I bought a used jd155C with about 400 hours on it. After about 20 hrs of use, the tractor just stopped and the drive belt was slipping on the motor pulley. Acts like I have frozen hearing someplace. Can this granny be rebuilt?

Hello. Replacing axles & seals on K 46. Do I fit the seals first and push the axles through or do I put in the axles first and put the seals on over the axles putting tape on each end to protect seal.

Hello. I have a john deere la150 with a k46

After 20 mins of use it won’t go fwd or reverse and loses power up the hill when it will drive. After letting it sit for about an hour it will go again for a bit then loses all power again. What parts do I need?

Please advise on price of a repair kit for a K46 transmission pumps seals filter ect

Requesting a rebuild kit for a John Deere LA135 T40 hydro transmission. I hear the k46 is similar and will be utilized as a rebuild kit. Could I please get a quote? Thank you!

I am looking for a K46C center case only are they still available and how do I order one if available

Hi I’m in Canada and I’m trying to find parts for my T40 hydrostatic trans. But when I go on web site it says not available.

Just replaced the pump bearing shaft and drained old oil. My John Deere dealer recommendations putting 10W-30 in for replacement oil. Is that ok or is a special Oil for hydrostatic transmissions?

Gus varna LGT 2554.

This is the 3rd right axel that has broken. They last about a year. K46. Kit # 1A646099891 fits. Can I just just the right axel. If sitting on the mower it is the axel on my right.

I am not remembering the orientation of the motor housing as stated above. Wide end up or down. Wondering if you could help me out. I have K46A S/N 46A-0036709 and JDHW p/n AM130447. Also would like to get a new filter, what kit would I need to order. Thanks

Tractor Tuff Torq AM135071 K62 Hydro Transmission. will this work in a John Deere G100 that had a K66 in it

I just received a rebuild kit .

The center section says T40 R14 and my old section has K46 R14 . Did I receive the correct parts ?

Small difference in the one pump hole is the only difference .

Hi I have a k62g and it has lost all drive. Do you sell the repair kit for it as I can’t find one anywhere in the UK or Europe

Qual viscosidade do óleo e posso usar? Pois não consegui encontrar o óleo tuf torq!

I wanted to buy TUFFTORQ K46 IDS FILER KIT.

While servicing K46 transmission I had several bits on a rag,cleaned & ready for fittment.One of the pups has ran off with the rag & lost 1 of the IDS filters,I have spent nearly 2 hours looking for it with no luck.I live in Australia & they are not available, even from my JOHN DEERE dealer?.

Can you send the 2 filfers if you can as the spring & body are fine.

Just let me know how to pay you for the filters plus shipping to Australia.

My addresss is as follows,

Trevor Pollock,

681 Branxholme Road

Knebsworth,

Victoria, 3286.

Australia.

Much appreciated,

Trevor.

Can I order parts from you directly

I have a Husqvarna transaxle

Tuff Torq 7A646084180

S/N 46BT0189876

I need the Piston assembly for the motor and the other piston assembly

Oil

Oil fill cap and breather

gasket sealant

Thank you

Todd Boulanger

I have a husqvarna 18542 with the tuff torq k46 bt 462120 that just had the anti debris kit and inversion system replaced what are these and how do I find them in case I need to replace them in the future?

i have 3 late model Simplicity Broadmoors one has a k62 tuff torque and the other 2 has tuff torque k57’s in them.why are these going out to the point where they won’t move forward or backwards a couple of them move then when it gets warm its slows to a crawl to the point i cannot make it back to the garage,they all have the cooling fins on the fans,there is no obstruction for them to not cool the transmissions,i do not have hills in my yard,and i just cannot believe i’m having a problems with all 3 and another thing they have good drive belts as well please get back to me on these issues,Thanks

Hi my name is Renee I have a John Deere tractorl130 will notmove forwardnot revers

Hello I have a k46 transaxle that is only two years old. The tractor craftsman 7800 pro series will not move forward not reverse., please advice in which parts I will need. I don’t believe I need a rebuild kit.

Just wondering if I can change (k46) the IDS from balls to screens without any issues?

Do you have a overhaul kit for?7A646024021 46C0174436

I have the D130 JD with the 768T2024011 transmission. The machine will no longer engage the transmission when the tow valve rod is pushed in. Whether in or out the machine will free wheel. Can you give me some info on how to repair this situation?

rebuild kit for Tuff Torq 787Q0824011 sn 7D-R0123131

Do you repair transaxles in house?

Thankx

Hi, I am trying to replace the shaft and pulley on my k51a tuff torq transmission.

. However when I pulled the old shaft out and tried to reinsert the new shaft there are 2 cylinders in the way. I can push them down and they seem to be spring loaded.

Have husqvarna lgt2654 with a tuff torq 7A646084091 S/N 46AW0065780 we need to know how to get the cap off to drain, repair, and fill with fluid. How do I get a repair kit?

Do you make a rebuild kit for a john deere gx255 it says Tuff Torq 7A637024020 71C-0000209 JDHW P/N AM133221

i have a craftsman with the k46 transaxle itook it apart too replace a bad bearing n ow foward igoes reverse what can i do too fix this problem

Hi, I have just refurbished my K46 transmission and replaced the pump, motor and gears. After I had it all back together I notices a small O ring on the bench and I have no idea where it came from. I looked at the assembly diagram and could not figure out where it may go. Can you provide any details on where the O ring needs to be. There are many O rings in the refurbishing kit but it says they do not need to be replaced. The one on my bench was like the the smallest one in the kit.

hi there, I have a mountfield 4155h 4wd ride on, the customer has been operating it on 2wd because hes been told the other axle needs replaced.Is there a way for me to identify this axle is beyond repair or can they all be repaired in some way.I don’t want to go just buy a new axle if it can be repaired? many thanks in advance

Hi, can forward and reverse be swapped around by installing the motor housing other way round?

Do you have a rebuild kit for a 46Z transaxle

Nevermind, I figured it out. After taking a break and clearing my head, I took another look at it. What happened was that when I tried to pull out the original axle seals, I pulled the rubber away from the metal band insert that gives the seal it’s shape and rigidity. That’s why it seemed like it was melted or glued on. Because it was at the factory where it was molded. With a little more force I was able to get that metal band out and was left with a nice clean opening for the new axle seals to go into. Sorry about all that. Maybe you could remove my previous post? And this one? Since it’s a non-issue. Thanks Again. Sorry for wasting your time.

Trying to replace the axle shaft seals on my K46BE. S/N 7A646084120. The seals (#72 187T0134280) that came in my repair kit (1A646099601) will NOT FIT in the original housing. Removing the originals was nothing like any of the repair videos I’ve seen. They almost seemed glued or melted to the housing. Took a lot of careful scraping to get all the old material off of housing. The chamfered opening is the exact diameter of the new seal, but the just inside the housing is what looks like a pressed in bushing. Part # 74 168T203424. So the new seal is so thick, that it bottoms out against that bushing before it comes anywhere close to properly being seated. Are the wrong axle seals being put in the repair kit? Should I remove the bushing? Which appears to have been pressed in anyways. (Doubt it. Also, don’t know how one would go about removing it anyway.) Also on the original seal….did you guys use some type of sealant between the outer circumference of the axle seal and the inner walls of the housing? Seriously, it was like the old axle seal was almost melted or glued to the housing. One other simple question. What does the acronym IDS mean? I.E. Ball IDS/Filter IDS Thank you for any help that would shed some light on this.

Don’t want to put that much money on this job just want the $71 cylinder block repair & the transmission seal service kit what is item # thanks ?

I have 125Automacic 100series JohnDeere

Prod. #GXO125A054310 model G125A

Transmission Tuff Torque # 768T2024010 AM1344582 will barely move forward or reverse Could you tell me what differential gear kit, filter, magnets with holder, and cylinder block kit I need. If i could get the parts numbers to order them. Thank You Happy New Year

I need a repair kit for a 2003 John deer L120C Date Code 050103 (759936 62506 0)

Can you tell me what repair kit I need and how I can order one.

Transmission has lost power and will barely back up.

I have model K46BN serial number 46BN001323, no power and no drive anything above half pedal in FWD directions, barely creeps in reverse direction. Took apart, oil looked clean and not filled with metal. Magnets had pretty good amount of goo on them. Also more noise from diff as hours accumulated. I’m assuming Center case with IDS Upgrade Kit good idea and recommended oil. Any other parts? Internal parts appeared to be in good shape still.

Hello. I have a k57a transaxle with a bad pinion assembly. The parts are no longer available. How can I fix this without junking the whole machine since I just bought the rebuild kit for the transaxle.

Will a transmission from a John Deere LA115 fit a L130? They look identical.

Do you sell rebuild kit for a L130 AM131580 Hydrostatic Transmission?

My Husq mower (164hrs) went from smooth engagement to jerky engagement to NO engagement in about 15 minutes of use. I thought the boots I was wearing might be causing me to not feel the pedal. There is no resistance in the pedal and the brake stop has no grass under it. Can you give me an idea of what the problem could be or where I should start looking?

Wanted a price and part number for a k46 transmission. It’s a 40j or mia10910

I have a john deere L120 with a (BAD) tuff torq k46 trans…….i have an opportunity to purchase a new in box k46 but its for a MTD Ser # 7A646084460. It looks the same but the axle shafts are different where/how the rear wheel attaches. Could the axle shafts from my l120 trans be swapped into the new K46 for the MTD.

THX

I am HP person disabled. I had someone rebuild my K46 tuff torq hydrostatic rebuild transmission kit. The man who did the job? Also change belt & both pedals bushings. John Deere x3oo tractor. Now the problem is tractor pedals forward going in reverse slow, reverse pedal now forward fast. Took transmission apart 2 times and check v block install correct. Please help spent my disability money to pay for tractor transmission. Help me please and thank you. Richie.

I have a John Deere LX277 with the K62 transaxle. It grinds when backing up but not going forward. it has plenty of pull going forward but appears to have less power when backing up. in your opinion what would I need to fix this problem?

I have a k51 tranny need a rebuild kit . any idea on what kit I need thanks

I need a rebuild kit for a simplicity tuff torq k57 transaxle what part number would I need and a ball park cost

Gerry, HOP 405384 .. 7A646084108 … SN 468T0117071

I have a K46BT hydrostatic trans Axle. I need a rebuild kit to replace the drive gears on the axles.

do you have or can you supply me with parts for tuff torq transaxle in ride on mowers

I have a lot 180 I need a pump kit the number is 746024021. 46-0146499 what number kit will work ? , don’t find any that match my numbers thank you

I have a K46 transaxle case PN 46BE0050278 SA646U84120 I took apart every thing looks great no shavings to speak of, it runs nice cold but when you go on any incline it stops, could it be the oil used it has about 300 hours when i drained the oil it seemed like there was not very much viscosity to the oil, The pump and motor seemed tightwith the plungers. can it get the tolerances for them please ty

I have a husqvarna lgt2654 with thek46aw transaxle in it. lately i’m having troble going up any kind of incline after the tractor is run for about 30 minutes. it runs fine up till then. i thought it was the main drive belt. i changed it, no improvement. do i need a repair kit of some kind

Hello I have just purchased a used John Deere LTR166 rideon. The rear axle has just snapped off at the wheel hub. Is there a chance of replacing just the axle or do I need to purchase a complete new transmission? Thanks in advance!

Thanks ggraham! Here are all the numbers off the bar code on the transmission. Hopefully you can tell me which model it is as it may as well be Latin to me LOL! Thanks! TUFF TORQ 768T2024010 S/N: 4OJ-0223283 JDPP PN: AM134582

Also…could you please tell me where I can get a transmission pump for this model.

Thank you!!

Hello My name is Rodney. I have John deere G100. The transaxle will not pull on a including. It has 400+ hours on it. What rebuild kit works with this transaxle?

I have a Model K45BA transaxle on a Craftsman lawnmower. What is the description/specifications of the belt that needs to be replaced?

Hi,

I have a K46 AM134582 in a John Deere LA120…A couple of questions please… How do I know which K46 model is it? IE, K46A or??

Also, my pump is gone in it… where can I get a new one?

Thanking you in advance!

Rex

I have a K46aw in my Husqvarna, I’m thinking of upgrading to a K57. Which one should I d use?

Bonsoir j’ai un tracteur tondeuse toro avec une boite hydro K46 1A646024160 ou1A646024163 Je voudrais savoir si vous vendez un quite de réparation car il avence plus quand il est chaud merci de votre réponse

I have a Troy Bilt bronco I have transmission leak around left rear axle .Is it serviceable and can I get a seal for axle.it is 618-07009 the serial # looks like 7A646084600

I believe I have a K46 trans out of a JD LT125. It looked like it had oil coming from vent and was covered in debris when I got the mower. It has 198hrs on it. I took it out, cleaned it up and did an oil change. Seems like I was wrong. All wet around neutral/in gear shaft and couple drips on floor after 2 weeks sitting. Is there an o-ring around that shaft or?? I do not have the serial number off the axle at this time…

Do you sell a repair kit for Tuff Torq K51A-SBR John Deere P/N 880202 ?

I have a hustler fastrak 42″. Do you guys sell a rebuild kit for the tranaxles or know of one? Or are they a disposable?

what is the clearance specification for the clearance between the pistons and the pump and alos the pistons and the motor? I need the specs. so I can know if I need to order replacement parts when I change the oil and filter.

Hi, Have a problem with a transmission in a John Deere Lawn Tractor/Rideon Mower.

No Drive – Forward or Reverse until the brake pedal is pressed approx half way down.

The mower has completed 426hrs.

No noises come from the transmission and seems to drive smoothly.

There are 3 Numbers on the Bar Code are :- 768T2024011 , MIA10910 & 40J-0858287.

Any help greatly appreciated as located in country Queensland Australia and the nearest John Deere service agent is approx 80 mile away.

Moro no Brasil tenho um microtrator husqvarna com transmissão K46, mas não consigo saber o tempo de troca do óleo da mesma e o pior, que óleo utilizar, com isso ela foi ficando fraca. Um revendedor do trator me indicou óleo sintético 5 w50, não encontrei o mesmo, me mandaram colocar o 10w40 funciona por 1 hora e quando esquenta ficar fraca, espera esfriar e usa mais uma hora. Acabei por trocar a transmissão por outra nova e não sei como farei a manutenção da mesma. Se possível me indique o tempo de troca do óleo e um tipo de óleo que encontre no Brasil. Obrigado pela atenção.

I am having trouble finding parts breakdown for a K46 transmission. I am hoping to get help here. The numbers on the transmission are IA 6460-89850 and IA 6460-24163. Looking forward to your response

Can I retrofit the limited slip to an existing k46 at the same time as repairing?

T he bypass shaft on my k51a tufftorq started leaking oil. how do I replace the new shaft with new one and put new O-rings 1a and p10a in. how do you get the old shaft out

46BL0031685 unit works great cold, and not so good hot. can I rebuild this unit? what is the kit# and the cost. Can you tell me of a local fluid so I don’t have to have it shipped. Thank you, Charlie power equip center.

Center case Service kit on a k46 transaxle

Can k66l be rebuit?

I need a repair kit for a k46 Tuff Torq transmission

SN: 46AC0184312

made

Reassemble k 51 a. Now forward is reverse and reverse is forward. What did i do wrong?

hi David, after servicing my k58a it now goes backward instead of forward and forward instead of backward is there a way to fix this? or should I just turn the seat around. thanks Gary.

Hi , I have a k46 s/no. 461-0011025 ( husqvarna 506 9863-02 ) and one of the ids valves was stuck in . I managed to extract both but there

was no ball bearing or filter in either , can you advise what is correct and pt. no. please ?

I pulled it apart because the mower has lost a lot of power and all looks ok apart from the gears in the diff so I have an enquiry for those

with a company here in New Zealand .

Regards

Bernard

Hi, I have a John Deer 115 which has the tuff torq drive unit and has lost all drive power. I was just wondering if it is worth repairing this by replacing the pump and motor kit or should I just scrap the complete machine. I’m not sure how much the repair kit is yet but I understand it is going to be quite expensive. (if the machine were working it would be worth about UK 450 pounds, aprox 550 USD).

Any advice would be most appreciated

Thanks Richie…

Good to know

-

I have a k46aw transaxle in my husqvarna. one of the axles snapped off . can i get a new axle?

Leave a Reply