Tech Tips – Residential IHT (w/ integrated reservoir tank) Oil Maintenance

Tuff Torq Oil Service Procedure for Residential IHT units with Internal Reservoir Tank

Models covered by this procedure:

- K46 Series

- Manufacturing ID: K46AA, K46AC, K46AG K46AW, K46BA, K46BC, K46BE, K46BL, K46BM, K46BN, K46BP, K46BR, K46BT, K46C, K46CJ, K4CR, K46CW, K46HD, K46V, K46Z

- K57 Series

- Manufacturing ID: K57A & K57F

- T40A & T40J

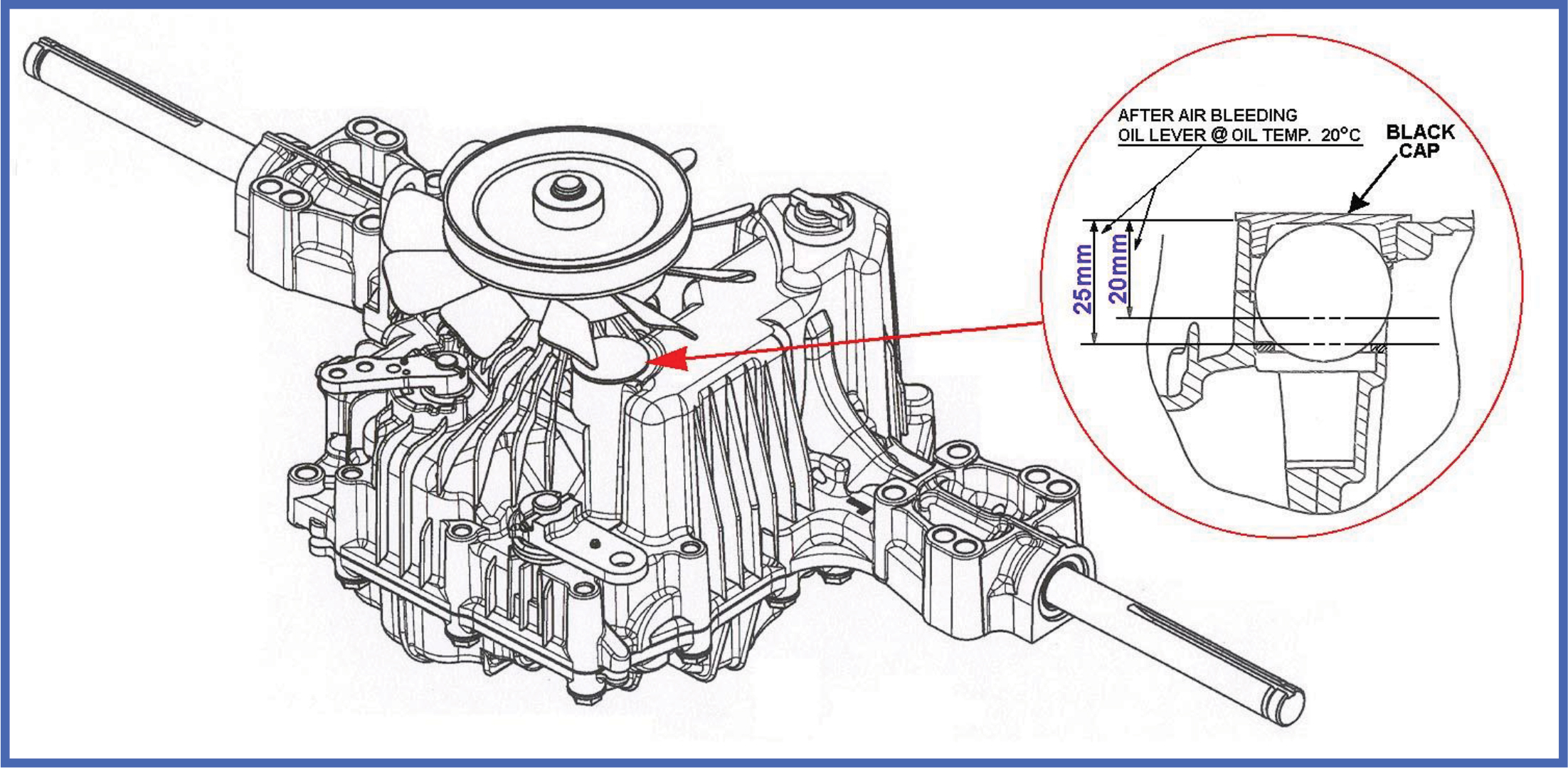

Normally the model K46 & T40A transaxles, that are featured in many tractor and rider models, do not require any servicing for the life of the vehicle. If checking the oil level/condition, it may be necessary to remove the transaxle from the vehicle. This is necessary to access the fill port (black cap) located under the pulley and fan (see diagram below).

After removing the unit from the vehicle, place the transaxle on a level surface and remove the fan and pulley. Then remove the black cap shown in the diagram below. Maintain the oil level at 20~25 mm (3/4”~1”) below the lip of (black cap) port (see diagram below).

Technical note: Check oil level when oil is at room temperature (20°C or 68° F) and the unit case is level and secure.

Always use the fill port (under the black cap) to drain the oil from your Tuff Torq unit. Do this by removing the cap and inverting transaxle.

Tuff Torq recommends using only using approved Tuff Tech drive fluid when servicing any of our transaxles. Only use the fill port (covered by the black cap) to refill unit. You will need approximately 2.2 liters of oil to properly refill the unit if completely empty. The amount of oil needed may vary for your service, due to the amount of residual oil remaining in case after draining and the condition/age of the unit you are servicing.

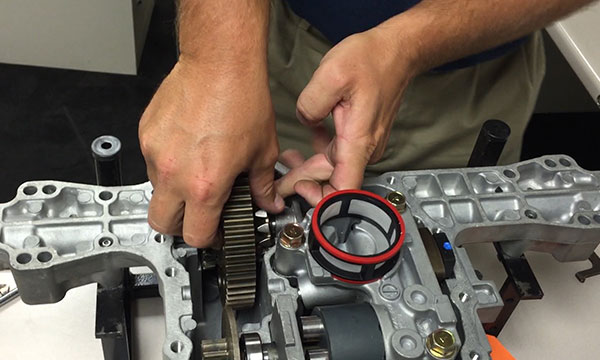

While reinstalling the fan & pulley be sure to place all components on the drive shaft in the reverse order from which they were removed and verify proper torque for each bolt.

Share This Article

mm

Good afternoon.

I’m based in Ireland & have a John Deere X300r ride on tractor with a K46 transmission.

During my first cut of the season over the weekend, i noticed that the mower ran slow after about 45 mins of cutting.

I checked the transmission & noticed that the fan blade was completely shredded.

I have a new one ordered, but was wondering if I can I just add the oil in through the cap on the breather tank to fill the axle?

Should there be a certain amount of oil visible in that expansion tank under normal circumstances, because I noticed that mine is completely dry.

Many thanks in advance.

I purchased a John Deere LT-155, which uses tuff torq transmission. What type of oil should I use? Some say 10W-30, however, I am not sure. Please advise.

i have a tufftorq trans axle K46BA model 917.289140 i wanted to know what fluid to put in or if Walmart hydraulic oil will work fine

Bought an LGT2654 used and three hours after running it around the farm, it started loosing power in the drive.

TUFF TORQ 7A646084091

S/N:46AW0126010

HOP P/N:448354

416 hours on the clock.

I checked the fluid and it’s and light tan milky consistency. Reminds me of moisture in the oil.

What color is the oil supposed to be?

Does this sound like a fluid replacement issues or should I just rebuild?

Hello.

In the UK with my K46 g , can I use a 5W50 Transmisson oil, or do I need a 5W50 Motor oil. I have ordered the trans oil as it is for mowers/tractors with hydrostatic trans. But upon trawling the questions you mention motor oil?

I AM IN THE PROCESS OF HAVING THE PUMP REBUILT FOR MY TUFF TORQ 46 TRANSMISSION. Will you please identify the correct filter and fluid that i need to order to replace after the parts are returned as well as the recommended gasket case sealant. My part number from the transmission case is the k461A6460-24162. the 1 in the number may be the letter I , Of that I am unsure.. By the way I called the website number to report that the catalog has no pictures and my part number cannot be searched. Thank you

1F218H20222 -2018

Model number 14B7A6CA010

Gx54 Fab D

Tough torque #7A632084830

S/n: 62AF0003060

MTD PN: 618-07281

1F218H20222 -2018

Model number 14B7A6CA010

Gx54 Fab D

Also, so anyways I pulled the battery. I have the black cap to the left that actually goes to the transaction itself and it’s about half to 3/4 of an inch from the top and then to the right of that I have the reservoir which is very very low. There’s only about 3/4 of an inch in the reservoir itself how high do I fill that and what fluid should I put in it? Any recommendations would be very grateful and helpful. Thank you guys.

I have a 2018 xt2 gx54 with diff lock I just hit 500 hrs want to change trans oil im getting very different answers from using 10w30 synthetic oil to 20/50 synthetic oil can you tell me what’s to correct oil to use thank you

Thank you for answering my question. Can transmission oil leak from the Tuff Torq Transaxle fill port or breather port if the machine its fitted to is placed on it side?

I have a simplicity Prestige, 2016 – The simplicity manual says to use 10W30 synthetic, is this okay?

I may have a bad axel seal and lost the fluid. I haven’t drove since but moved it 20′ and it was fine

I just want to add oil in the reservoir. Thanks in advance

How do I remove the black cap on the fill port and then how do I put it back? This cap seams very tight and If it breaks what do I replace it with?

Repuestos,en dónde,en ARGENTINA??

What is the cost of a 3-liter bottle of your Tuff Tech oil? I have a K51A transaxle. How can I order it?

I have a JD L111 from 2005 with around 450 hours on it. When doing some repairs on the tractor I noticed the fan blade on the T40 were all missing but one. I pulled it out of the tractor. The magnet at the fill had almost no metal shavings. I am replacing the fan and the oil. Do I need to check the internal filter and/or replace any of the seals or just let sleeping dogs lie? I do not see any leaks.

Very helpful for several reasons, in ordering identified parts as well as assisting others ! Thank You…

Do vent valves or caps ever need service or replacing?

?

Hola, tengo un outils wolf a80 pro, tengo que sustituir el transeje cual sería el que corresponde porque no veo el K46w que sería el suyo

Hello. I have to change the oil on a K46AC in a John Deere X165 due to hot running. Thinking of filling 5W50 oil for motorcycle since it contains additive to protect gear and clutch. Or should I use regular synthetic engine oil?

This is very helpful, I have a 2010 John Deere x300 with a Tuff Torq K46BR. I drag around an aerator with concrete blocks, a thatcher, and a large utility trailer with a yard of bark, and the rear end is starting to groan a bit going uphill (without any extra weight other than my 200 lbs). I suspect some parts are worn but I’m hopeful that pulling the transaxle and replacing the oil will give me another 5 years. I’m wondering, however, whether I can pop off the air valve to check the oil level and top it off until I have the time (and the will) to pull the transaxle. easy to access the valve, not so easy to get to the fill port.

Can I use synthetic 10w30 in a k46bt?

K46I on Husqvarna Rider155: I want to confirm I can drain from the 2 drain plugs on the bottom and refill using the oil tank on the top.

Simple question, I know, but I don’t want to mess up.

Good afternoon. I have a John Deere mower LR175, with TUFF TORQ 7A646024051 46F-0137928 CASTEL GARDEN 18400950/1, can you tell me the exact type and capacity of oil for this mower to fill up?

Thank you

Hello. Could you please tell me the fluid type and amount for and LX176 John Deere mower, Tuff Torq K46F-0126185. Is John Deere HI-Guard oil suitable or not? Thanks

I have a John Deere 125 Automatic. I repaced the drive fluid and put it back together nowI cant get the axle to ingage. I spin the pulley and pull the lever that hooks to the pedal and nothing. The axles will turn and the pulley will turn but it wont work together. the tag on the transmission is

Tuff Torq 768T2024010 S/N 40J-0017809 JDPP PN: AM 134582

Thank You for your help

Terry Dimmer

Need help on draining and filling 7A632084690

In the diagram in manual for cox lawn boss it has two drain bolts. Can these be used to drain the oil without removing unit, also has a resivor above can this be used to fill.

I’m planning on changing the oil in my lawn tractor that has a k46bt transmission this summer is it okay to use 10w 30 full synthetic

Do you not have a RESEARCH AND DEVELOPMENT TEAM to design and build a transmission with a site glass or plug easily accessible for checking and maintaining levels between regular scheduled service.

[ have a john deere LX-188 stock # 8063043 SN #1678881 I looked on Transmission and found Tuff Torq # 129351 the tractor has a 17 hp kawasaki water cooled. the tractor has very few hrs. it was stored for a few years in shop . it has a leak coming out of seal at brake. it traveled for about 200 ft. and stopped traveling . i drained oil and it was milky. dropped tranny and filter screen was caked over with oil. while i have it down i feel a complete re-boild is wise thing to do . gears are i great shape. i just need to know what re-build kit i need.. thanks for info you can supply to me. John Deere refused to work on it for they couldn’t get parts from John Deere.

How much trans oil is in john deere x350

Hallo, mein Tuff Torq K46 7A646024051 S/N 46F-0181342 Einbau im Honda 2417 läuft Vorwärts einwandfrei die Rückwärtsleistung ist dagegen gering, Öl 10W-40 wurde gewechselt,

die Leistung war vor und zurück voll da aber nach 30 Min hatte der Rückwärtsgang kaum noch Leistung .

I have a T40J and live in North Florida where heat is our biggest enemy. What hyrdo transaxle oil spec should I use for the most protection and longest life? I don’t want to go too light or heavy to impact performance but I need protection from heat breakdown.

How to make seals Last longer. Rider is in use obout 6mounths a year. What oil do You recommend if I don’t get tuff torq oil.

Bonjour, sur une boîte 7a632084581s/n j’ai deux fuites d’huile. Une au niveau de l’arbre de roue et l’autre au niveau de l’arbre de verrouillage (pour pouvoir pousser la machine à la main).

Sur l’arbre, il ya beaucoup de jeu au niveau du roulement (est-il compliqué à changer ?) et c’est un joint spi qui fuit.

Sur l’axe de verrouillage, l’opération est elle compliqué afin de changer ce joint, faut-il ouvrir la boîte ?

Merci

Please tell me if trans 7A646084020 K57R-0184399 HOP PN: 437814 is a replacement for 7A646084180 S/N: 46BT0000304 on Craftsman 917. 276681 rider year 2006?

Simple install or lots of work?

Stuck without info here folks as no parts websites, not even Sears shows what trans to use for this unit, its trans is shot.

Thanks

Thanks! I’ve been changing the oil in my K46s’ for several years now. I have moved to a new home that has a very sloped yard and was wondering since most of my mowing is going up and down now, can or should I put a heavier weight oil (straight?) in the trans-axle instead of the recommended lighter weight?

Hey I run a small engine shop. I have two John Deere mowers. One model number on transmission is 768t2024011 and the other ends in 4010. What are the differences in the two? Can I swap them as one no longer works on one of the mowers? I have found they are both labeled as T40J online that’s why I am asking. Thank You

Hello, I have a John Deere D120 lawn tractor. I’ve replaced the hydrostat, now it won’t pull itself up an incline. Suggestions for what to do next? Thanks!

Can a k46v be installed on a JD Lt160 that had a K46C? What is the difference between the two units?

husqvarna k46 ia6460-84161 oil seals. dealer gave me a number of tuff torq #187t0134380 but they are somewhat larger.what is the correct number please.

I have a Snapper 2691282-00 SPX 2548 48” fabricated 25 HP Lawn Tractor 150 series with the Tuff Torq K46BL transaxle, when I first purchased the mower everything worked fine, but now over the years the forward gear still works, but the reverse is barely working most of the time and when it does it is really slow, any idea as to what would cause this problem? Thank you!

Hallo zusammen,

Ich habe eine John DEERE LT 166 aus 2001 . In dem Traktor ist die John Deere Nummer Am 880203 verbaut.

Können Sie mir sagen welcher Achstyp das bei Ihnen ist ???

Aufkleber auf der Achse ist nicht mehr vorhanden .

Danke

Schirmer

Recently I broke the long shaft in my mowers k46 transaxle. I order a new shaft and seals and fitted them as required before topping off with 5w40 oil. All went well for about 25 minutes then I lost all forward power and had very little reverse power. There were no visible leaks around the casing and the oil level in the reservoir was low despite having put in 2.2 litres, any ideas as to the loss of power before i remove the case again?

I have a K46BA0096113 trans in my craftsman mower. I removed the air vent cap and plug to check the oil level. How do i reinstall the plug and cap? are they supposed to be attached to each other? I ordered a new vent valve and the plug did not come with it. Can i reuse the same plug with the new vent valve? How does it get installed?

I have a k46 AW transaxle and broke the drive wheel axle, is it possible to change this shaft? If so will I need all new seals when I split the case open? I’m handy but not a pro by any means.

7a646084100 no neutral noise at slow speeds and can’t reverse up grade seems slow little plastic washer broke by shifter bracket pivit

I have a Husqvarna yth24k54 with a rear axle serial number 46BT1233972. It has 405 hours on it and I finished cutting the grass and was in the process of pulling a lawn sweeper and the trans started to whine, and within 500′ or so it shuttered and stopped. The axle was covered in oil and it was dripping. Upon removing the axle, I found the cap had dry rotted and cracked, which caused the leak. When I drained the oil it was a dark brown/grey color. No burnt odor to it. I am hoping that I can refill and put a new cap on it and it will be fine. The magnet did have a thin layer on it. I am trying to figure out exactly what axle I have. The tag number is 7A646084181.

I have a k46c transaxle s/n46c-0011168 on a john deere lt 180 tractor . i need to know what position the wedged shaped block needs to be thick side up or down? is the narrow part of the block ever up ?

Why is my k46 grinding when I press the gas in and could the trans pulley be out it’s low on drive fluid but will that make it grind like that

Good day,

I have a gearbox No. 7A646084170 (K 46 BP) in a snapper. After 25 minutes of operation, this loses enormous power. (has 200 operating hours) Can you also change the oil on the gearbox and does it improve?

Need to replace axle seals leaking but concern about if the bushing should be replace because of seals leaking but I don’t feel any play in the axle.

How do you put grease back in after replacing axle seals

I have a K46 in a Troy Bilt Mfg. date Jan 2015. Serial number is not readable on label. Transmission # is K46 1A6468-29902 (the 68 could be 66 or 88). Tractor does not move unless it is running for 15 minutes with pedal depressed for the entire 15 minutes. Then is will inch forward a couple inches, after another 5 minutes inch forward again and then slowly pick up speed and operate fine until it is shut off and cools down. Transmission is remove and I see the fill cap. Cap is intact but deteriorating and afraid it my crack when removing it. Is the cap available if needed? Also what oil can I replace with after draining case? Any thoughts on why forward or reverse movement is non-existent. Until if appears oil warms up?

Is there any way the air purging procedure can be done with the transmission out of the tractor? The reason I ask this question is, I cant top off the oil once the transmission is back in the tractor. My John Deere is a 135 unit. Thank you.

my rider mtd 13a n601h729 work great in forward gears but dont want to work it want movie in revene

And also how to check if it’s full of oil on the K46BT

K46 oil capacity and type of oil pls

OK, so I got to the “rubbery” black cap with the transaxle still on the mower. How do I get that cap off? Can’t find a “lip” or anything. Undersatnd there is a magnet under it as well?

Fluid type and amount for and LX188 John Deere mower.

Tuff Torq 19154-24122 upper case

Hi, I have a JD L110 (but it has the 20hp vtwin when i bought it) with a K46. I only use it during the winter with a snow blower attachment. It goes forward ok, but has so much less power reversing. im thinking on changing the oil (drop-flip-refill) what would you recommend for oil if it only sees winter service -20F TO 40F mostly in the +20.

do you think new oil might improve the reverse performance?

If i see the upper magnet with a lot of metal, i would consider opening it up, so far no evidence of leaks on the shafts

I have a K46 and the serial numbers are unreadable. How to tell what parts to order?

Hi I got a K46BN trans and is in neutral cant foward or back ward any help????

My 2006 Countax X series (20 ) 4 wheel drive hydrostatic mower is leaking oil from the Tuff torq K574 gearbox, the rubber oil seal needs replacing at the top of the gearbox casing, sealing the shaft assembly under the cooling fan. Can I replace the seal from the top without removing the gearbox ? Can you please advise. I believe the oil seal part no is 187T0134380 Many thanks.

For my Husqvarna YTH21K46 with a K46BT transaxle, could I increase the travel speed by installing a slightly larger pulley on the engine shaft, or would that not work with this type of transaxle?

I have a k46bn trans.how much for a rebuild kit?when it gets hot it won’t pull.does fine for a couple hours,then too hot and won’t pull.

Your table “Fluids and Lubricants” does not specify the type of fluid used in the K46BT trans-axle, could you provide that info? Thanks

I rebuilt the rear end in my lt 160 but when you push the petal to go forward it go in reverse what did I do wrong

I realized now that I used the wrong port to fill unit. Can you put in to much oil in the transmission? (K46A2)

It moves if the wheels are off the ground. But when they touch the ground the tractor will not move.

I didn’t see what port to use until I looked up on Tuff Torq Oil Procedure.

k57r transmission in a husqvarna yta24v48. noticed black gear oil is leaking out of my right rear axle tractor only has 60 hours on it after i replace the axle seal how do i top off the gear oil that leaked out and what weight oil do i use? and what part number is the axle seal.

hello where can i find parts in Belgium . where can i find more info how to calibrate the fulcrum at the 46 f gear ?

I do not find Tuff Torq transmission oil in the shuswap area. Please tell me the cross reference info so I can use automotive trans fluid.

Can I buy parts to repair my k46 in my jd lt 160 tractor?

Following the recommended oil change procedure I’ve noticed that when the drive shaft at the top is being turned. clockwise on my K46AC, and the freewheel lever is disengaged I can grasp the turning portion of the axle (right side) and it simply stops in my hand. Is this normal?

Could I replace a K46BC with a K56? Are they the same size, with the same mounting points?

My shop was flooded in Hurricane Harvey. I am afraid water got into the transaxle. The top of the Tuff Torq was under about 8 ” water. Should I split it apart or just drain and put new oil?

How do you remove the black cap seems to be stuck on? I am trying to refill the fluid because it has been leaking a little bit

what are the differences between a k46 and a k46ac

I have Ariens 46″ Lawn & Garden Tractor, 22hp B&S and i would like to change the hand gear to pedal gear (using Husqvarna YTH 20K46 parts)

I have a question about K46 hydrostatic transmission. Whate are the main differences between K46ba (Ariens) and K46bt (husqvarna) hydrostatic transmissions. Does theoreticaly hand transmission connections fits with pedal transmission parts?

I have a tuff Torque K72 High speed transmission, and I would like to know if there is a service manual for this unit that I can get to better help be keep it maintained properly.? It’s in a 2017 Simplicity Prestige tractor. The owners manual that comes with tractor doesn’t cover good technical maintenance.

Thanks for any info you can give me.

Wanting to know what the cost of a pump and motor for my K46 transmission would be. I’m doing a rebuild on it as the mower would not move in forward or reverse.

Thx

Leave a Reply