Tech Tips – Residential IHT (w/ External Expansion Tank) Oil Maintenance

Oil Maintenance Procedures for Residential IHT units with External Expansion Tank

Designed to be trouble-free

Normally the Residential IHT (K46), which is featured in many tractor & rider models, does not require any servicing for the life of the vehicle. However, if there is a desire to check or replace oil, it may be necessary to remove the transaxle from the vehicle to access the black cap located under the pulley and fan. Due to the design of our units.

Maintenance Overview

First, remove the transaxle from the vehicle following OEM instructions. After placing the transaxle on a bench surface remove the fan & pulley and pry open the black cap and remove magnet (see Fig #1). Invert transaxle to allow the oil to drain from case through the port under the black cap.

Tuff Torq K46 Oil Maintenance – Figure 1

Refill transmission case with oil through same port to near top of the case. Tuff Torq® recommends refilling transmission with Tuff Torq® hydrostatic oil, available from our service and aftermarket department.

Reinstall magnet & cap. While reinstalling the fan & pulley on drive shaft be sure to place all components in the same order as they were removed.

In heavy usage applications, oil changing is recommended after the 1st 50 hours of operation and every 200 hours, thereafter. The filter should never require changing unless the transaxle is removed from the tractor or rider and opened for repairs.

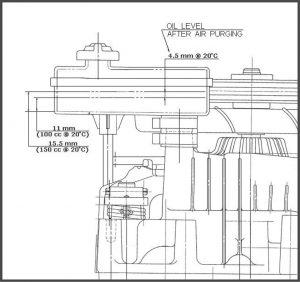

Finally, after purging the transaxle of air, add additional oil through tank opening (under vent valve) to the recommended oil level. (see Figure #2 below for recommended oil level).

For more information, or to order your service parts and accessories, please visit our service website here. For technical support, you can call our service team at (866) 572-3441.

Tuff Torq K46 Oil Maintenance – Figure 2

Share This Article

If the transmission does not need servicing for the life of the vehicle as you say, then are you going to warranty my transmission that went out while mowing my yard? It seems to me your making a product you are saying will last for the life of the vehicle. That is an implied life time warranty. Mine did not last so it should be replaced.

Appreciate the detailed guide on oil maintenance procedures for Residential IHT units with External Expansion Tank! Addressing the tractor problem is crucial to ensure smooth operation. Regular checks and proper oil refilling can prevent potential issues, keeping the machinery trouble-free

I have a john deere L120 with the k46 transmission, it wouldn’t go up hill when it got hot, l changed fluid which made it a little better. Is there anywhere in Australia l can get parts from to suit.

Hello dear Graham, I am Jalal from Iran, I am a mechanic. What kind of oil should I use?

Just purchased a k46bn. Does it come with oil in it? And if so how do I purge it?

I bought a new k46. Just wondering if it comes filled with fluid already??

I have a K46 AW in my Husqvarna that will not go up hills. I can get to and remove magnet and oil appears low. What weight oil do I need? Will it fix problem? do I nned to bleed air afterwards?

What weight of hydrostatic oil Do I need for my K46B Tuff torque transaxel.

I believe I have a k46 in my husqvarna xt48xls. I had lost ability to climb inclines so I drained and refilled the trans. Seems to work okay until it warms up and then barely moves up the slightest incline. In fact, if the wheels are turned it’ll barely push forward. Any suggestions? Perhaps a heavier weight oil is needed?

Hello, thank you for comment -369602

One last question: if I remove the lower case, would it be able to remove the lost magnet? Or do I need to disassemble the entire unit to find it?

Thank you very very much!

Hello, while repositioning the magnet in my Tuff Torq K46, it fell down and into the case below. No way to fish it out.

What are the risks of running the unit with the magnet inside?

Thank you for your kind reply

I am draining and refilling my K46 in my LGT2654 Husqvarna

How much fluid do I need, How do I purge air from unit, is this before installing transaxle or after?

Thanks for your reply

Where can I purchase this fluid locally , at Lowes, Tractor supply?

Just received new K46. Do I need to add fluid or is fluid already in new unit?

What type oil do you use in a k 46 from factory

cannot drive on slight incline??? no problem on flat

I purged it but nothing, what should I do?

I have a John Deere LT180. Cannot drive up slight inclines. No Power. OK on the flat. Do you know who supplies the K46 transmission in Australia.

My k46cc has no power on inclines . But is fine on flat ground. My John deere has 500 hours on it . Is there anything that can be done?

Thanks

I have a 2008 Husqvarna with 1076 hours on it.. It has a Tuff Tork K46 BT in it… which has never been removed or serviced.. after 15 years & 1000 hrs… just now starting to hesitate & slip.. especially in reverse.. The oil is about 1” below the full mark… My question is … (with this many hours) can I just add new oil or do I need to open it up and replace the filter too?? The oil was very dark… almost black!!

if purchasing a complete new tuff torq gearbox for a john deere tractor does the unit come filled with oil/fliud as its really a sealed unit or would you have to fill new gear oil ?

my neighbor gave me 2 husqvarnas – lgt-2554 and a lgt2654, both have been setting for 4 to 5 years. got the lgt 2554 running great, the lgt2654 was drop off a truck and broke the axle shaft. is the tuff torq k46 worth rebiulding? or part out the lgt-2654, how much oil does the k46 take and what weight oil is in the tuff torq k46?

I need axle bolts for the K46 on a cub cadet XT1

I have a John Deere X304 with a Kanzaki K46 transmission. Its making a oud grinder or screeching sound after it warms up after mowing the lawn. Its a 2 hour mow job.. Also I’ve overheated the trans while aerating the lawn a while back and tractor doesn’t seem a fast as it used to be. How much oil does the trans take and what is the oil change procedure. Do you folks sell the oil and or oil change kit?

Hi I have a countax D18-50 . Problem is the power steering will only turn the wheels if you spin the steering wheel really rapidly then it will turn to full lock ok, same for both ways of steering . I have changed the trans oil and filter but no better. Any advice would be appreciated.

Loosing what looks like transmission oil from LHS of axle , just started and now is continuing, is there seals or something I can replace or where is it coming from

i removed the transaxle from a husqvarna yth24k48, question about being a k46 tuff torq axle. drain about 2 1/2 quart, bleed the air out, axle will spin, however, i can only add 68 oz. and i looked up the amount and it said 73 oz. the axle is top up with new oil, still have 6 oz. to go but the oil level is top out. is 68 oz. enough oil for the axle?

We took in a Husqvarna LGT2554 that had no transmission response at all, and the previous history on it is murky at best. We changed the oil in the K46, and put the correct amount in. We now have power through the unit, but reverse and forward motion are backwards to the lever. My question is: Are there internal variations in these transmissions that can accept CW versus CCW input directions? Like I mentioned before, someone might have put a different transmission in the machine. Thanks

I have a A646024380 s/n JDPP PN: AM131575 46V -0330729 is it fixable it will run for about 15 minutes the lose movement and hardly goes up small incline , let it set for 5 minutes then it will move again , change oil and clean magnet , don’t go into small part of transmission, just open it and clean the housing . Thanks what do I need to do to fix it

How do you purge the transaxle after refilling it

Hello,

I have a tractor with a k46H. What recommended weight can be pulled on a trailer?

Hi, I have a JD LTR180 it has a Turf Torq 46 A -0052930, as you look at the machine from the back, the right side drive shaft has snapped, is it possible to get a replacement shaft to fit this machine, other numbers on the barcode lable are -: 7A646024003 S/N, JHWP/N AM 130447. What type of oil should I use in this axle. Hope you can help.

Can trans oil be changed on the Husq yt48xls. If so, q usnity and wt of oil or atf.

HI I have a new JD x350 2022, I noticed that the mower can be pushed with no resistance when the trans is engaged. Is this ok.

Hi, I have 220 hrs on my 2015 John Deere X300 with a k46 tuff torq trans, it started to whine so I replaced the fluid with Tuff Tech premium transaxle fluid . I turned the shaft to purge the air, had some bubbles. Installed the trans in the tractor and suspended the rear off the ground and ran tractor in forward and reverse, the wheels turned slow. When on the ground the wheels barely turn. Do you think air or something jarred loose with the fluid change. Thanks John

Hi, I have an MF ryder with Tufftorq 7A646024400 S/N: 46Q-0007532

After 15 minutes, it stops. What oil and filter do you recommend.

I need a dealer from Europe who sends parts to Croatia.

Thank you! Matthias

Hi Tuff Torq, I have a K46C-0057102 with 590 hours that was functioning well. While fitting a new drive belt and pulleys to the mower, I also drained the transmission oil and refilled with John Deere HyGard. Since refilling the transmission and repeatedly undertaking the air purge process (out of the mower and installed on the mower) the best I can get is a creeping pace (but strong – will creep up hills) on the mower with just a small input of forward drive – if I further depress the forward drive pedal I lose all forward movement. I only get forward movement with minimal forward drive input. Do you have any suggestions as to what the problem might be? Many thanks.

I have an Ariens Hydro Tracor and according to the book it has a Tuff Torq Transaxle K46BA. It is beginning to slip while mowing. I have replaced the belts and they are tight. Do I need to change the oil in the transaxle? If so how do I do this?

I have aSullivan 40607 319-0500 Hydrogear transmission to change trans fluid type?weight

Hello!

I have a transmisioin K46IA6460-24I62 with the symbol: 7A645024340. On the occasion of the mower renovation, I decided to change the oil. According to the instructions, the box should hold 2.3 liters of oil. I poured about 1.5 liters and the box is full … Is it possible that I missed a step when draining the oil? (when draining, the crate was turned upside down)

Hi, can you advise if K46 can be purged before re installing in the mower ? Or advise how to top it up once reinstalled in mower, when accessing the black cap and magnet appears to be impossible? Regards Ian (Australia)

Hello, Do you have a workshop manual for the k46e, in particular showing how to change the seals

Hello I have a Husqvarna YTH2246TDR mower-K46 transmission

Its is 10 years old but only has 35 hours on it (was in storage for many years)

It has just started to loose forward and reverse motion when it gets hot after cutting for 45 plus minutes.

it has always had a slight pump cavitation noise when operating.

Belts, pulleys are all in excellent condition.

I am really disappointed that it should be having issues with such low hours.

Any advice please?

Thanks Peter.

-

Ggraham,

Thanks for your response,

Fluid was milky – water contaminated.

Filter had a lot of congealed fluid in it as well, so flushed everything out and reassembled with new fluid.

Back to normal again with no cavitation noise even in the Australian heat.

Appreciate your response and assistance – well done Mate.

Peter.

Hello. For K46H (60mhr) better 5w50 or 5w50.

Thank You

Do zinc/phosphorus oils additives such as ZDDP Engine Oil Additive add any benefit for longevity?

Would adding such an additive hurt?

Thank You,

Bonjour, j’ai commandé le kit de réparation complet tuff torq K46, celui ci est arrivé avec une différence comparée à ma pièce d’origine, le système IDS.

Je n’ai pas de forage dans ma pièce d’origine, et donc pas la pièce métallique dans la boite sur lequel les pistons poussés par les ressorts du système IDS viennent s’appuyer.

Pourriez vous me dire comment je doit remonter la nouvelle pièce?

Merci

Its funny. Tuff Torq says the k46 is a reliable transaxle. But everyone seems to have similar problems. No power can’t climb hills but yet we are expected to spend more money on repairs. I have a John Deere X300 that is 6 years old That has less than 150 hours and I can not use to cut lawn. It is realy a shame that we spend $3000 on such in inferior product and the only help is we are told to change fluid which does not help or we have to purchase a new trans axle which will only last a couple of years. Why don’t you improve your products to last longer and make them so we can change the oil easily.

Hello,

my transmission loses power after 5 minutes of work, the tractor does not move, but when we lift the tractor we take the weight off the wheels, it turns normal, at high speed, what could be the problem?

thankful

Rodrigo

I have a D140. I can barely make it up a slight incline. I have MIA10910 768T2024011 S/N: 40J-112555. I have been offered a K46 1A6460-24163 transmission. Will it fit and work?

Hi,

I have a K46CR 0134345 7A646084321 from a 2014 Husqvarna YTH2242TDRF.

I can’t find any info on the CR model, do they take the Tuff Torq 5W50 187Q0899000 oil?

I can’t find this oil in Australia, will Mobil 1 5W-50 full synthetic be ok?

Is the filler plug p/n 168T2036300? (Husq 583348601)

thanks

where in australia can i buy a filler cap for a k46 hst

Hi

I have a Tuff Torq 7A646084020, SN 57R-0078188, PN 437814.

What oil should I use for this?

Thank you for your help

Left rear axle broke on transmission need diagram to order part

Thanks for your prompt reply, a number of things have changed my mind about repairing the current installed trans-axle one of them being NO DRAIN HOLES!

Is there anyway that you can x reference the TuffTorq part number and the JD part number to find an axle that has drain holes and preferably an Eternal Expansion Tank for a higher capacity of fluid, if you could check this out for me I would be so grateful.

Cheers, Frank.

Hi Graham,

My mower is a JD- L130 with KOHLER and 48inch deck bought new circa 2003 JDPP P/N AM131580 TuffTorq 7A646024390 S/N 46AC0147458

My questions are- What is the full K46 model number, is there a repair kit available and what was the original fluid/oil?

Many Thanks for your time

Cheers, Frank.

I have AM131580 S/N 46ACO167689 tough torque transmission, can i use 5w50 full synthetic or should i use J20C. My L120 JD stopped pulling so i checked linkage and belt and found all ok so i removed unit and took cover off and the filter was clogged. I inspected all internal parts for wear but didnt seeanything but very fine scratches. Your help is appreciated.

I have a 2006 john deere 115 automatic lawn tractor that has done 1000 hrs. The hydro drive is a k46 iag460-24163. The PN AM134582 the SN 40J-0067947 also has this number on the bar code TUFF TORQ 768T2024010, I have drained the transmission completely and want to refill it with new oil.

I cant get tuff tech oil, but I can get TURF GARD will that be ok to use or should i be looking at 5w50 considering the hours.

My Husqvarna ride on mower has a Tuff Torque 426121 has limited and intermittent forward power (slows down to almost stop and then starts to move forward again and then speedup) but appears to work well in reverse. The machine has done 900 hrs so it getting pretty old. I have not checked the oil nor never serviced the transmission. Any suggestions on what might be the cause?

John Deere LA110 won’t go forward or reverse however if I put tractor rear end on jacks wheels turn but with no power. Could it just be low on Hydrostatic Fluid?

I have Countax fitted with gearbox p/n 7A646084280, the fwd/reverse input lever moves freely back and forth with no drive from the gearbox, could you indicate what the likely failure is? The tractor had started to struggle to go uphill and had been moving slower and slower.

Craftsman T210 with the k46dm. Had 0 issues on my last cut. This time on the 2nd pass, mower was going slower and slower till it wouldn’t move at all. Checked belt and and linkage. Checked fluid level by removing batter and removing cap. Fluid level was fine however magnet was heavily coated. If I press petal as hard as I can it will barely move and some grinding noise is present. Should I replace the transmission or would I be fine with the rebuild kit?

I have a 2008 John Deere X300 with a K46 Transaxle. Want to change oil to determine if that will impact issue with “power loss” going up hills. The only number I see is stamped – 5473964. What type oil and how much will I need?

What kind and How much oil does a 7a646084091 hold?

Help please!!..I bought a tractor with k46….runs great for 15 min then won’t move!…replaced oil with no better results…any advise?

Hello Graham,

thank you for fast reaction! 🙂

Have a nice weekend

Bert

What type of oil is recommended for my hydrostatic drive L130 mower 7A646024390 S/N

Good day,

I own a lawn tractor with a TuffTorq drive No. K460 S / N 001483 GP Jaromer P / N 358698.

I would like to add hydraulic oil to the oil expansion tank. Which oil can I use that is also available in stores (location Europe, Germany)?

Regards Bert

What oil is used in my lawn tracker. It has a tuff torq trans. Serial # 085354

-

The serial number is stamped next to the fill. John Deere LX178

I have a tuff torque 7A646084591, SN 46DMO746112 trans on my Craftsman model 247.27042. When going up a hill you can hear a slight whining . It has 113 hours. I’m wondering if I need to change oil ? It does not seem to slow down going up the hill but the whine is there. Any recommendations ? I bought the mower Sept 2018

Thank you

can you remove case bottom with trans still in mower, will anything fall out? doing to do drain plug kit, i can access fill plug without fan removal.

Olá o meu trinco a parte de baixo da caixa 46AW0170771, preciso do óleo e a quantidade, porém as autorizadas aqui em Valinhos SP BRASIL ninguém sabe o correto

I will be replacing the oil in a Craftsman lawn tractor with the K436BT transaxle. Sears part number is 7A646084180. what is the weight oil and capacity? Can OEM oil be purchased from a local vendor? we live in eastern Iowa. Thanks

I have a 51A and wondering what the oil level in the tranny is supposed to be I’ve done a full rebuild of gears, shaft,pulley and resealed the case with new oil filter and fresh by5W 50 oil ..what is the level supposed to be in the small port / fill area? Large fill area doesn’t have the magnet on a key 51A does it? Just a large spring that holds the filter and media between the gear case and the pump and motor area

I have a Tuff Torq K46 axel no 5473964 . When we try to mow the grass it seems to slow down and then just quite. I have had this mower since 2016 with 1859 hours on . I was wonder what the problem is ? I talked to a mach and he told it is the pump is going out . He told me to drain the oil and put in new AMS oil 100%synthetic trans fluid Sae 20W -50 .I’m going to change it now and see how it works the mach said I may get one more year out it . Was wondering how much a pump for mower would cost .

How do you purge the air?

Hi I have a Husqvarna with a k46 transaxle. I loos power on the uphill after mowing for about 30min. Any suggestions?

How much oil should I put in. And what type will be the best.?

I have Tuff Torq K46BR /7A646084220/ SN 46BRO347139, which is included on my John Deere X300 riding mower. I’m experiencing huge losses in power after mowing hills; seems to be a common problem. I intend to replace the hydrostatic fluid. Please advise on recommended replacement fluid and volume for my unit. Thanks.

i have a viking t6 which has great power going forward but struggles in reverse. Any ideas

Hi, based in UK. have a 2002 Westwood t1800 with the K46 hydrostatic gearbox. all going well and absolutely no issues, until last mow when i noticed as i parked her back in the garage a patch of oil on the floor related to the rear axle. no power issues. up on jacks and the undersurface of the box is wet with oil, no obvious leak point. reservoir fitted under the seat is at a jaunty angle for some reason and is also wet with oil. was cutting across a lot of inclines and wonder if the oil has leaked from the reservoir due to severity of incline and poorly fitted cap; seem likely?

on a flat surface its tipped to the left by 30 degrees.

2nd question, what should the level be in the reservoir? full to brim? or room for expansion? tank is at a jaunty angle and not level as i said so somewhat difficult to tell residual volume.

3rd question, can i just top it up?

thanks for any advice!

My mower has 480 hrs on it and it feels like it might be slipping more than ever going up hill. Oil has never been changed, do you think that might be the problem? I did change the drive belt and it still slips. The transaxle gets warm also

Hi,

I am from UK. I have Year 2002 made Countax C600H. The gear box/ transaxle is Tuff Torq K46E. S/N 46E-0020057. The drive is struggling on an incline after it gets hot.

Is there a service manual for this transaxle. What hydrostatic oil do i need to use for a change of oil.

Any suggestions would be deeply appreciated.

K46BA craftsman 21 up transmission whining mower stopped middle of cut

Drive belt on looks good All connections ok Plan to remove transmission

I would appreciate direction & comment Right repair kit and price on new or rebuilt transmission

Hey I was wondering what kind of fluid does the hydrostatic k46 take.

I have a fleet of 3 mowers, all with Tuuf Torq 7A64 transmissions (MTD PN 618-07208. All run hot after extended use, but one developed this: It starts out fine, but over time it begins losing torque. It’s not as noticeable on a flat, but soon climbing a slope becomes labored and eventually it won’t make the climb. After a cooling off period, it starts out fine again. No sign of belt slippage – it remains cool to the touch. What could be the cause?

Hello just wanted to know if you still do rebuild kits for a k51a-sbr s/n:075164

have tufftorq k46cr for Husqvarna mower. can left axle only be replaced without replacing entire unit. right side working fine.

Can you give me a price of the fan (426120) at the top of the K46TB transaxle. Our mower wiring harness fell into the fan and broke 2 fins off.

What was the reason why a simple drain plug was never installed on your transmission? Thus allowing for a much easier way to preform a fluid change!

Bonjour,

J’ai un COUNTAX C800H, occasion qui a 225heures, le carter inférieur de la boite hydrostatique est abimé, suite certainement à un problème

sur le différentiel et réparations …la boite est référencée

7A645024041 S/N K46E –0037289 — Ou peut-on trouver une boite neuve ? ou Les boites K46 E pour countax C600 sont-elles les mêmes ?

On en trouve des neuves pour C600 sur le web…

EPINAL VOSGES FRANCE le 30 Avril 23021

What is the difference between a K46 and a K46BE?

Tuff torq 7A646084181

What are fluid specs, type and capacity?

Is it ok too use 5w30 motor oli in K46 7A646024362

Witch Oil type can I fill in for a 7A646024003? S/N: 46A-0063461

Can I use regular Tractor Hydraulic fluid found at a Fleet Farm or Napa store in my K46CA Model # 7A646084460 S/N 46CA0042560

Can put tell me the oil level and and weight for a 7A646084321 the pic isn’t very helpful

J’ai une transmission K46 AW et je trouve 2 numéros de Pieces très semblables sur internet J’ai le1A646034131 et 1A646034131 13 es ce la meme chose es ce que ca fais sur le k46 c aussi es ce la meme essieux

What oil does Tufftorq put in replacement units?

I have a E170, bought new May 2020. It can barely climb any slight hill. Tried to pull my dethatcher (40″) and it could barely pull that. Since new it’s a gutless mower, can barely pull it’s own weight around. Was hoping it needed to get broke in, but after 20 hours its still a turd. Is there something I can adjust or should check?

JD La130 looses power uphill,but goes fine backwards uphill.

I have a Husqavana LT 2654 when it gets hot I lose power climbing hills and comes to a stop, I have had it to 3 dealers . The first one said new transmission,(so we did) ,2nd said that the drive belt is glazed,(so replaced it) . Now the 3rd replaced belt filled transmission oil , still having the same issue ,he now says it could be a oil sending unit ! Please help before I put it out of it’s missery

Oil

Spect k46c-0077661

Hello,

I have husqvarna yth 1848 xp riding mower.

Does it have the k46 transmission?

If so is the 5w-50 is the right transmission oil for it?

hi looking for a hydrostatic transmission Tuff Torq K46S thanks. I am in Italy..

Bonjour, je suis possesseur d’une autoportée Stiga équipée d’une boite Hydrostatique Tuff-Torq 7A646024362, celle-ci fonctionne bien à froid mais commence à avoir des faiblesses lorsqu’elle est chaude, c’est à dire après avoir travailler 1 heure. Je ne connais pas le passif de cette machine. Il y a deux possibilités, soit l’huile est fatiguée (il en manque peut-être) ou la boite présente des signes d’usure. Quel est votre diagnostique. Merci.

Can I use gel-lube during reassembly? Some of the little pins and such are quite hard to maintain in position while assembling.

Can I add a external tank to my K46 John Deere 300 , at this point it doesn’t have any, just bought this and it whines when backing up, also can I add the oil change plugs and what oil can I use to get greater longevity?

Ho problemi con la trasmissione7A646024340 dove posso spedirla per essere riparata?

Why would tuff torq make a transaxle that must be taken out to change oil

Hello.

I have Husqvarna LGT2654 and is about 8 years old. When is hot outside and mower get hot I lost power and completely stop.

Read a lot what is going on.

Most likely transmission. What do you recommend in this. Remove it and change oil, buy a kit nad fix it or change it completely for new transmission.

It is K46 do you have upgrade for this kind of model or stick it with K46?

Thank you.

Hello, I am trying to rebuild my K46 unit but having trouble finding the kit specific to the model number… maybe you can help model # 7A646804180

Thank you

Hi again. Since my comment I’ve found that the input pulley and input spline are stripped. Label reads Tuff Torq 7A646084030 S/N 46A10004335. Can you advise an agent to supply parts? Thanks.

Hi, I have a Seco Starjet AJ102/15,5 01 mower. That suddenly lost drive. fan and pulley on top spin but just a rattling noise instead of movement. Any suggestion of a fix and service a agent in New Zealand? Thanks

Warren

The speed on my K46 is great in reverse but in forward it is much slower. Any thoughts? It has been slowing for some time and gets worse as the machine warms up. New drive belt has not solved the issue.

Hi I have a john deer L100 can you recommend a kit for fitting a drain and fill plugs

hello,

I have a lawn mower with a TUFF TORQ 7A646024410 S/N:46T-0037116 box. What oil should I use?

thank you

hi. i have stripped my 46k transmission because i found the seal on the resivor was missing..it had a large amount of dirt and grass in it. because of this i stripped the unit down to give it a complete clean..all went well until i started the motor and tasted the transmission..found the direction pedals were reversed.

how do i correct this problem,i thought i had followed all the information,and no parts over..any assistance to remedy this fault would be appreciated.

cheers stephen

have a John Deere 960r tran. leaks from the top I think around fan is there a rubber seal there can it b replace

I have a 2010 John Deere X300. Tuff Torq 7A646084220, S/N46BR0291902, PN MIA 10959.

Which seal kit do I need, and if I break any case bolts where can I get replacements? Thanks

Buongiorno, informazione che tipo di olio e gradazione devo montare sul cambio tuff 7A646024340 S/N . non riesco trovare un tabella un riferimento !! Grazie saluti Gianni

I have a John deer L100 it is coming up to 150 hrs and I’d like to change the gearbox oil your thread gives a good description of what to do thank you

can you please email this picture. It printed out to small and not all of it.

Bonjour j’aimerai savoir quelle quantité doit ton incorporé dans la transmission ,comment faitont pour éliminé l’air,mon tracteur est un crasfman 24 hp avec une transmission 46k0819505 (7A646084181)merci de `m’aidé

My Husq yth22v46 with a Part #7A646084181 SN#46bt134395. Is there any interchangeable units that will work with it?

Resized_20201105_140342.jpeg

Hi is this JD Hy-Gard trans oil (pictured) the correct oil for my K46BD trans

Thanks

kjg

Needing to rebuild or replace transaxle on John Deere LT180. Having trouble identifying the correct unit. Tag on axle says:

HOP PN: 426120

Tuff Torq 7A646084181

SN: 46BT0774054

When I search on this info it seems this is for a Craftsman unit. Can you help clarify?

Need help troubleshooting K46BA transmission. Control level forward or backwards, no motion. Drive belt in great condition, tight and turns while motor running. What is not working properly? Any help would be greatly appreciated.

I have a John Deere 345 with K70 transmission. John Deere says to use low vis hydraulic oil but your chart shows 10 W 30 motor oil. which is the better choice?

My TUFF TORQ transaxle tag is 7A646084180, s/n 46BT0315800 ,HOP PN 405384. My parts manual list transaxle as PT#532 40 53-84. I find on the web the substitute part number is now 532 42 6120. My wheel axle is broke into. Is the part number 532 42 6120 the correct part number for me to order?

I can’t buy from that site. because it is in the States and I am in British Columbia Canada. Do you have any outlets that I can buy Tuff Tech Oil from in Canada? Thanks ~~ Dan

Cub cadet LTX1046KW with 520 hours, used to cut manicured centipede, Suggested fluid change? Having no problems.

I see online that a lot of people are using 5W50 full synthetic oil, is that a good oil to use? My Transaxle no.s are. Tuff Torq 7a646084321 — S/N 46cr0120448 — HOP PN: 426121 I thank you for your help in this matter. ~~ Dan

We are in southern BC and do not get as cold as farther north does. The noise happens all the time, summer and winter. I let it run with the brake off for a couple of minutes to warm up the oil, it still does it but not quite as bad as when I first start it up. I also have a snowblower that I use on it with Chains and wheel weights on the rear tires with a counterweight on the rear. So I do use it in cold weather but the noise is not any worse once it warms up.

I have a Husqvarna yt42xls with the k46 transmision. 5 years old with 256 hrs on it. Cold the transmision whines badly, gets less noisy as it warms up but is still loud. Pulls ok all the time either cold or hot. Should I be concerned with the noise? Thank you Dan

There is a clunking noise in forward drive in my John Deere D-160 but not in reverse drive. It has just 88 hours total time.

Any guess as to the problem?

I have a Husqvarna YTH2348 W/ a K46 Transmission ans I need a rebuild kit for the hydralics in the transmission. You asked me to get the transmission numbers off of it. they are: Tuff Torq 7A646084181 followed by the serial number: S/N 46BT0523468. there is also a HOP PN # of: HOP PN 426120

I HAVE A CRAFTMAN YT 3000 AN LOOKING TO CHANGE THE TRANSAXLE FLUID, BUT NOT SURE WHAT TYPE OF OIL AND WEIGHT TO USE. DO I USE A SYNTHETIC MOTOR OIL OR A HYDROSTATIC TRANSMISSION FLUID?

When servicing by transmissions 7A646084460 on my riding lawnmower I am at the point of removing the black cap to drain and refill. I am having quite a time prying that cap off the transmissions. Any recommendations?

I have an 8 year old Cub Cadet LTX1046WK with a TUFF TORQ 7A646084460, S/N 46CA0013939. The reverse is very slow and now the transmission is noisy and slipping. Is all that is required a fluid change. Also, not sure what is meant by an air purge when doing a fluid change?

Hello, I have a Husqvarna YTH2348 with a K46xx transmission with over 700 hours. Mowing fine today, uphill and level. Had a few hard jerks, then stopped moving altogether, both forward and reverse. any thoughts?

Good day, I have a Husqvarna YT48XLS Model# 96043015500 with a K46 CR/LD transaxle. When it is cold, it will climb hills fine, but after it warms up, it will not climb anymore. Level ground is fine. I’ve never changed the transaxle fluid. Do I need a new transaxle or is there hope for just a fluid change? I have no leaks, and no other issues

Hello, I’m repairing a K46AC S/N:46ACC0100281 and I’m looking for repair parts delaers in Guadalajara, Jalisco, Mexico.

Also want to know alternatives to the OEM fluid and fluid capacity. Thanks in advance.

I own a Husqvarna YTH2348 w/a K46 transmission. Last year I noticed that after it getting warm, it started sounding like a bad power steering pump and I figured I’d change the fluid, but to no avail. when it heats up (I am mowing a very hilly property) it loses it ability to climb. I was wondering if there’s a pump assembly or something to rebuild/replace? When it’s cold while it’s loud it works fine. after about 20 minutes it won’t climb. level ground it’s okay. any suggestions on what I can do?

Hi I have owned an LTR180 from new 2005 yesterday it stopped driving and it looks like the drive pulleys have collapsed. The machine is for home use and has not been worked hard, I have taken it my John Deere dealer for repair, I will ask them to change the oil, do I need to go any further than that, internal filter and so on?.

Thanks Steve

Hi just bought a 2020 jd e170 an I have read a bunch about the k46iht an was wondering how durable they are. Mine has the k46be iht any info would appreciated

I have an LTR180 Deere, k46a trans S/N 0037761complete loss of drive. at first struggled on hills not just get a slight movement going back or forward.

On inspection of disassembled trans some slight chipping on spider gears not a lot of metal on magnets. had a paper filter (new replacements I see are screens) Is it possibly just a dirty filter? all plungers in pump and motor seam tight no lateral play noticeable. since apart I was going to replace gears & new screen. pump and motor are fairly pricey if they look fine should I need to replace these assembly’s?

and if there is some wear to these assembly’s would a nice heavier synthetic be advised?

Diagram and instructions very helpful thank you Tuff Torq.

Good morning I have a Husqvarna 24hp 54 p. Cut. Replace the entire transmission for loss of strength.

I need to know what oil to use in the new box since the one recommended by you is not available in Argentina. This machine is for intensive use and slopes. Thank you

My mower runs great till it warms up it gets slower and slower till it stops it is a craftsman Tuff Torq 7a632084620 S/N 66y-0009465 Hop PN 199973 this is not the first one that heard of that went bad could it be oil your is it likely in the pumps.

Got a 2015 craftsman t.t. 7a646084590.

S/n 46dm0181550

Mtd p/n 618-06972

Has 76 total hours on unit has hydraulic whine and peeformance deteriorates as warms up. Do i probably need overhaul or should fluid and filter do the trick.

when I use a lift to raise the front end of my riding mower [k46 transmission] oil drips onto the floor. I know it’s from the transmission. can this be some kind of failure of the vent valve and cap? I had to add a good quart of oil to the trannie when I lowered the machine and it did not move at all.

After changing the oil with 5-40’s synthetic and cleaning the box my K46F runs a lot quicker in reverse than forward although I am convinced I replaced the tapered plate which fits onto the piston unit and alters the direction. Do I need to open up the box and refit the tapered plate.

Regards

Nigel

Two #s. 618-04270B or 103EH3D276 hydro-Gear. What oil and best way to drain it . To bad no recall on them.

The kind (Weight) and amount of oil for my Transaxle. Number on tag, Tuff Torq 7A646084320. HOP P/N: 417213. S/N: 46CR0003147.

One comment said 10W-30 syn. Another comment said 20W-50 syn. The amount I removed was 2 quarts.

Thank you,

Don

I have a 2011 cadet slots 1050 mod #13wq92apo010 s/#1b231h60046 drive belt replaced will not go up incline in reverse is the recommended oil 20w50 oil motor oil or hydro oil appreciate any help.

I have a cub cadet xt2. The turning radius is listed as 18″, but I have trouble try to turn at twice that radius. The back tires dont seems to have a differential gear and just push the front tires straight ahead. Is there something wrong with the transmission?

I have a YTH24V48 I just bought. I doubt if the fluid has ever been changed. It has 187 hours. I would like to put 5W50 in it. What can I expect to pay at the dealer to have this done? I believe this is a 2013. I have the model and serial number but can’t seem to find the info. Product # is 960450046. Serial is 012814A010040.

Can I use aw32 hydraulic oil in my transaxle transmission instead of Tuff Torq k46 oil?

-

Hi there, I have read your negative comments regarding the Tuff Torq transaxle and all the problems and repairs carried out. All I can advise is to try out some new Pullyes! Ypu’d mentioned an oil-change and also that the drivebelt had been replaced. If 100% properly purged (sounds simple but actually isn’t), well then if now power it can in my humble opinion still be a drivebelt issue. How to check this? After running it and noticing the slipping, stop the engine and get off, check directly by touching the drive pulley on the engine and over the drive axle. If these are warm or even hot, well then check by looking at the pulleys exactly where the belt runs. If all shiny well then the slipping is obvious and the heat confirms this. Then and although you’d previously invested in a new drivebelt you still have slip!

how much does the k46 hold for oil with out the extra tank

Hi Guys I have a K46f transmission but the pistons have started to stick. Have tried to order a replacement cylinder block 168T2025090 but the part appears to be unavailable in France. Can you advise me if it is possible to order a part or even the pistons and springs

I sure learned a lot after reading the article. Many thanks.

Hola buenos dias tengo mi k46 que no luego de calentarse no avanza ya cambie el aceite como me recomendaron y no hubo mejoras debo reemplazar las partes hidrulicas me pasaria el pdf de las partes por favor gracias

Would like to upgrade transmission on JD e140 Tuff tourq 787T0124010 SN AAK00006736 as there are no level areas in my yard What is available direct fit no mods with locking differential ,and at what price .

K51a trans what oil and how much does it Hold

I dont fully understand the oil level.

Just fill until it is 4.5mm from the top? Seems like a lot of oil

I have a Westwood S1300 approx 2009 with a K46 transmission, after about 1 hour of mowing it loses drive going uphill, it is ok on the flat. Do I need to just change the oil, if so do Ii need to remove the transmission or can I draw the old oil from the reservoir tank.

I have a K46 in my 2014 cub cadet is there a way I can beef up my trans for mowing hills? Gets hot after ahwile for mowing so much just changed fluid out

I have a leak in my JD L120 K46 transmission coming from the left rear bolt. I discovered a trail of oil up the drive and into the garage with a fairly large amount of oil in the garage. The apparent amount of spill would appear to be more than what is leaking from the bolt. I don’t see any evidence that the oil spilled down from the top of the trans yet it seems impossible that much oil could have come out through that slowly dripping bolt? The bolt was tight. What might cause this situation? What is the likely hood that the internals are damaged and a full rebuild is necessary?

What are the thread/specs of the 114 fan bolt on the k46ca? Part# TT-1A646083090. Could it be replaced at a big box stores or is OEM necessary?

Cub Cadet Model #13W1A4CA010. Loss of power up hills. Axle seal was bad, leaked all the trans fluid out. replaced the seal, used 15W-40 motorcycle oil to replenish, better power now, but still hesitates. am I better off rebuilding the trans or is there another trick I could try? If recommended to rebuild, where could I purchase the rebuild kit. This Transmission is K46 ETC. Also, the mower had ran for quit some time before the notice of any power loss. at one point, the mower stopped moving forcing me to troubleshoot and repair. Also, when i went in to fill the fluid, had to replace the fan as there were no blades on it (who knows how many hours of operation under this condition). Thinking the trans overheated, blew the axle seal, leaked out the fuid, (because i was stupid and didn’t notice) continued using all up until it totally stopped moving.

I have Model # 40A-01250943 in a JD L108. Its starting to whine. Want to change the fluid. Is this the K46 trans, and what fluid (vicosity) does it take?

Thanks.

I have a Cub Cadet LT46 with k46 drive in it. I can cut for about an hour and after that it quits moving. Any info would be great on this. Just oil change or rebuild? I am leaning towards an oil change cause when it does pull it pull great with no issues. I have cleaned all debris from around it to make sure it’s breathing good. Fan on top is also good.

I have a John Deere L130 with 7A646024390 Hydro. It will not climb inclines anymore. Is rebuilding it ok or will I run into the same issues. What options are available ? This tractor still has strong motor and deck.

Thanks Jim

Hi,

I have a 7A646024041 which has a small leak from the right shaft. Just wanted to confirm it is just the seal that is likely require repair (Seal 19*32*8) and if this can be replaced without breaking the unit down? Also it barely moves when under load after being used for a half hour. Replacement oil?

Thanks

Thanks for your reply Graham have opened the box and found 3 pistons ceased so have ordered a new cylinder

Regards

Nigel

I want to remove the KK46BR-JOHN DEERE / 7A646084220 on my 2008 JD X300 to change the oil. It may be sluggish on hills but otherwise this is preventative maint. and the first maint for the K46. I have no leaks or other issues other than sluggish on hills. Is it worth me splitting the case for inspection and cleaning magnets or am I better just to get the TT3 in it and leave well enough alone? Hour meter is @ 261

I recently topped up the transmission Oil on my WESTWOOD T1800 TUFF TORQUE K46 HYDROSTATIC Transmission.unit

I think I may have overdone the volume because since the top up I have oil leaking from the transmission on the garage floor which appears to be coming from the bottom of the transmission unit particularly after use . Should I be concerned I have caused any damage or. should I let I simply continue until it reaches a level where it not overfilled …thanks for your help

I HAVE A LGT 2654 HAVING TROUBLE GOING UP HILLS. DRIVE UNIT 7A646084091

I have a Husqvarna LGT2654 with drive unit 7A646084091 that is leaking oil at the control shaft seal. Is a replacement seal available? If so, what is the part number?

Thanks in advance for your help.

Hi GGraham sorry but have a problem with my K46F drive unit After breaking down the box and inspecting all parts cleaned everything and filled with new oil. My test drive was ok for 10 mins but felt as though the IDS was jerky then all drive stopped both forward and reverse. Your previous advice was to replace the input drive shaft I have not done this as it seemed ok but will if necessary. I will breakdown the box tomorrow but would be greatfull for any advice. Regards Nigel

I am trying to purchase the spline shaft for a John Deere LT 155, 38″ deck, MOL155B025410. I am assuming I will need to flush and replace the filter. I had trouble trying to log in.

I bought my tuff torq last year. It did good for the first year. this year It started cutting grass foreword and reverse no problem. then It quit,will not go in any direction. what is my problem? I probably put 12 hours on it last year.

My tuff torq stopped moving. When I removed the transmission and drained the oil it was milky. Would that cause the transmission to malfunction?

The thin metal pipe extending approx 2″ from the external reservoir down to my K46 is free to slide in and out of the transmission casing, and leaks. the larger diameter connection also leaks. Can you advise on the failure and the remedy for both these leaks, please.

Thanks GGraham

Nigel

Hi guys

Could you let me have the part no for the modification to be fitted to my K46F. The mod is a flat bracket fitted with 2 extra magnets and is fitted on top of the drive / pump unit with 2 of the existing 3 bolts

Happy Easter

Regards

Nigel

Hello I have a k46. I had a Bearing that broke and replaced and changed oil. And only works for 5 minutes. I dumped oil out and refilled it and only runs for 5 minutes can you help

Bonjour,

J’ai vidangé ma boite k46h par les 2 vis de purge situées dessous. J’ai refait le plein par le réservoir externe. La partie Gear est remplie mais la partie hydro ne se remplit pas.

Faut-il remplir par le capuchon noir ? Si oui, quel est le niveau recommandé pour une boite avec réservoir externe. Je pense qu’il faut remplir au maximum pour que l’huile coïncide avec la partie Gear.

Dans l’attente de votre aide. Merci d’avance.

Thanks GGraham for your reply do you have any info, parts list to help me with my limited experience in opening up the unit any advice gratefully accepted.

Regards

Nigel

Hi guys

My honda 2417 hme mower (2006) is fitted with a Turf Torq unit 7A546024051 with external oil tank and s/n 46F 019174

My problem is grinding noise from the unit so could not find the drain plug but managed to get some of the old oil out and replaced with 30/50 multigrade engine oil as no hydrostatic oil available. The mower still grinds in forward and will not go uphill but not bad on flat ground, in reverse the mower grinds occasionally but climbs uphill no problem. Could you suggest a solution

Regards

Nigel Teale

Has anyone tried washing out the K46 with gasoline to get more of the old oil and metal residue out?

Is that a good idea or not?

Hello,

I have a k46; is there a torque setting for the bolts that hold the bottom sump on. My bolts were loosened with the intent to drop the sump but this was not required so the sump was not removed or the seal broken.

is the magnet that goes under fill cap available by itself–I’m changing oil an mine is broken in pieces–k46 transaxle

In a K46 rear end you are saying to refill with 5w50 synthetic, right? Could you at lucas oil stabilize as well? Also have automatic hydrostatic oil 56 would this be any better to help the rear end from heating up?

I have a k46. I had to cut out the fill cap to remove it . I see there is a steel cap. Would that replace the rubber one?

I have a K46 in a D130 that is gets hot and slows down and blowing oil out the fill plug what can cause this

I replaced the original k46 transmission in my x300 which wouldn’t move once it warmed up with a new replacement k46br from john deere. I now have 15 hours on the new transmission, how often should I change the oil in it so it doesn’t do the same as the first one? What is the best way to drain the oil out and where do I get new oil for it?

Why does tuff torq recommend 5w50 over the original 10w30 for most applications? That is a significant viscosity change, I could understand switching from the original 10w30 conventional to synthetic 10w30. But why to 5w50? Thanks for your time.

I have a K46 transmission (I believe) without reservoir that is in my John Deere L130 S/N GXL130A117878. I know it should take 2.4 its, but how high after purging air should i have the level? Up to where the magnet sets so once it heats up it runs past or all the way to the top with magnet installed? Thank you!

what is best way to purge a K46DM on a cub cadet?

Hi there, is it possible to reinstall the same cap after removing? I removed the upper plug and drained mine after I had a main drive gear failure. I’m about to install it and reassemble my mower, thanks in advance

I have a husqvarna yth24v42ls and I recently noticed the k46cr to be leaking fluid. Is it possible that changing the fluid would resolve the issue? Thanks so much.

Have a great day.

I have a k46v how much oil it take to fill

what is the total amount of hydrostatic oil do fill a tuff torq K46 transmission?

If the Tuff-Torq 918-07009 rear end is completely empty how much fluid should it take to fill it ?

ive got a tuff torq 46c the only thing i see is a side screw port is this where i check the fluid level and also fill it also axle seal is leaking how do i get it out and install new one do i need to remove axle and split it thanks very much for any accurate advice

I have a 2016 Cub Cadet XT2 Enduro Series GX54 (26 hp Kohler/54″deck). It just started leaking oil from the left rear wheel seal area. I thought about replacing the seal and have been advised there is a cap on the top side under the seat/battery area to top off the oil. I have not checked this yet but if so, what would be the best oil (10w40?) to use to top off? Thanks a lot!

How much oil does this K46 require?

I have d160 2011 does it have the k46 . I want to upgrade to the k66 can it be done and fit

I have a lhusqvarna 24 48 with a k 46 transmission worse good forwards and reverse but is freewheeling going down hills and can be pushed without pulling release wire will oil change help this

What fuild should be in a k46bt

what is the recommended procedure for purging the K46BR after replacing the oil?

-

I have the lt155 can you tell me how much fluid in the trans

Hello.

Tuff Torq K62G-0004340(For Countax).

What should be the cold oil level in the external expansion tank ? Currently this level is very low and I don’t know if it’s normal

Thanks for your response

Good Morning

can you change an Axle bearing from the outside.

regards Trent

I have a Simplicity Broadmore 44 with a K57 in it. Sticker says K57 only. No R, A etc. Will a K57R fit it?

I have a John Deere L130 it has k46 rear end in it I’m fixing to change the oil how many quarts of oil does it take and what kind oil ?

I have a k46 AW what does the AW mean

How effective is syphoning out oil and just add new oil.?

Hi, My K46 is still jerking for about 5-10 minutes from cold, after which it is fine. If I pre-heat the gearbox to say 85F, it runs fine out of the garage.As the oil has been changed for a 5W-30 does this suggest that there is internal damage? Thank you.

-

Dear Sirs, I have a 2554 Husqvarna lawn tractor. I had a problem with it when it gets warmed up it doesn”t want to go up hills. I took the transaxle out and disassembled it. the only thing I seen any wear was the springs in the motor and pump. All pistons and cylinders looked very clean with almost play or wear on the chrome of the pistons. I replaced the springs with new ones, put it back together. and it goes forward in reverse. and backs up in forward. Can you tell me what I may have done to cause this? Should I have replaced the pump and motor?

Hi, Recently (for the 2nd time) the left rear axle on my Craftsman mower broke at the point it enters the transaxle housing. I mow about 1 acre on flat ground and am wondering if this is a weak point on the axle. This K46 is about 6 years old – the first one was about 3 years old when it broke. The first time the dealer sold me a new transaxle and what I have for numbers are K46BN 7A646084160 468N0046861 – The numbers are coming from my paperwork because the units do not have the sticker on them. I kept the original transaxle and am debating on attempting to just replace the broken axle or replacing the mower. If I opt to repair either or both units is that doable for someone with fairly good mechanical abilities or does it get technical? Also are there repair parts available?

Thank you for your time……..

HI, I’m looking for a specification of the transmission my CastelGarden tuff torq PIN 18400965 s/n 7A646024410 46T 0644136.

I appreciate if U would help me in.

My K46 has started hesitating/slipping and growling when cold, forward or reverse. Cold here is say 5 celcius. After about 10 minutes of use, I get full power no problem. In the summer it’s fine all the time. Belts , pulleys and linkages are good.

I topped up the oil last year and it seemed better, but it seems much worse this winter.

Any ideas?

Thank you

What replacement sizes will bolt up to the husqvarna LGT2654. Came installed with the k46.

recently parched a used D110 John Deere. want to service transaxle. need diagram/parts list. new oil type and viscosity. have watched videos and will tackle trans axel soon. need a good exploded diagram of Axel.

What is the difference between a k46c and a k46a? Thank you

HELLO!

I have a 2018 John Deere E140 with K46.

If I press the foreward pedal harder I go faster. If I press less I go slower.

Am I riding a clutch to go slower ? Will this damage the K46 ?

Should I always press the foreward pedal fully ?

-curious in Crescent City…

~thanX!!

~Mack

I am looking for T40J hydraulic pump maximum PSI. I could not find anywhere in either tufftorq nor kansaki web site. Do you know where to find it?

Hi, will any k46 fit a John Deere Lt180

Sorry, one more thing. I assume the transaxle is a K46.

I have a Tuff Torq transaxle and the following information is listed on its ID tag:

TUFF TORQ 7A646084321

S/N: 46CR0090284

HOP PN: 426121

I obtained it from an older gentleman who liked working on lawn and garden equipment. For health reasons, he reluctantly had to stop. He had this transaxle, but couldn’t remember what model or brand of equipment it fit. Very clean unit. Drained the oil (only 1/2 quart approximately) but it was pretty clean and contained no metallic particles. Magnet under fill plug had a slight grey film – appeared to be from normal wear and tear. If you could tell me what equipment it would fit and whether or not it appears to be ok based on the oil and magnetic observations, it would be much appreciated. Thank you.

Will k46 hydrostatica axle work in a L LT155 deere

I re did the seals in my tuff torq k46s transmission. Now when I press the forward pedal it goes backwards and the reverse petal it goes forwards. Anyone come across this before?

Hello, changing my fluid, can you tell me the capacity for my k46 please.

7a646084321. S/n 46cr0078626. Thank you!

Hi I have a k46 bt what is the adjuster and lock nut on the right side for and how to set it. How much oil does it take.

Hello. I have a k46bn on my husqvarna gth2654, i recently broke the left axle somehow and i am trying to figure out what axle repair kit i need for this transmission. Thank you

Hi. I have a countax with a K46E .

On start up the mower will not move but if you give it a push and drive it for 50 yards it is then fine..

The mower is 15 years old and had moderate use

Can you help?

Can I use 15w-50 in the transmission. I have 3 quarts of it already.

Sorry one more question…. The sticker on my JD D160 K46 says 7A646084121. Can you tell me the oil capacity?

How can you “purge the air” with the transaxle on the bench? I’ve read the procedure to do it with the transaxle installed, but on a John Deere D160, I’d then have to pull it back out to top off the oil since there is no access to the top of the transaxle.

Also transmission has to come out doesn’t it?

I have an lt 166 j.d. and have noticed a little oil on the back of the gas tank. I’m guessing it’s from the transmission and seems like it’s lost a Little pulling power. Do you have an idea on fluid capacity and fluid type? Any help would be appreciated

We have a Cub Cadet ride on the mower will work for awhile then starts slowing down going up hill. Oil was never changed in it. Can it be low on oil or has the oil broken down so badly it has ruined the transmission? There is 220 hrs on the machine but we cut hilly terrain . Thanks Glenn.

Pulled transmission apart changed oil put back together/ now mower goes forward on reverse pedal and forward on reverse pedal, what hav we done wrong.

I have been readng all of the Q & A and will be draining the trasmission and changing the oil and am considering adding Lucas transmission additve. I would appreciate your input on this.

Husqvarna YTH24K48 I understand it uses a K46BT transaxle. When stepping on peddle for forward motion there is a long delay, tractor starts to move slowly until getting to normal speed. If stopped it restarts just as slowly. In reverse no dely at all. Engine runs fine, rpms remain constant. 144 hrs on tractor about 5 years old

Hello I have a K46A transaxle and I took it off the unit as it would run for 20 minutes and then stop moving. I let it rest for 20 minutes after the oil cooled down and then the unit would run for another 20 minutes. I just saw a video that showed how to drain the oil from it and noticed that there was hardly any oil in the unit, and whatever I was adding thru the air vent would come out after it heated up. Could it just be that I need to add oil to the unit and put it back together instead of rebuilding it? The unit does not whine or make noises when it moves but after 20 minutes it stops. Thanks for your advice!

1870 Christopher Trace Is the center section on a John Deere what makes in go in forward and reverse ?

Will 20w50 work in a k46

Hi,

I have a K46BE in my JD L130. I changed the filter and oil using Tuff Tech recommended oil. The trans drive belt started to slip badly. I replaced the belt and much improvement. But, it still slips going up a grade, even with a helper spring on the tensioner. Do I need to go to a lighter weight oil? I read that JD uses 30 weight.

I HAVE A TUFF TORQ K46DM HAS RED FLUID LEAKING FROM BOTH AXELS. JUST WONDERING WHAT TYPE OF FLUID SHOULD BE IN THIS? This tractor is 2015 with 90 hours on it… not sure if I should change the seals or the fluid?

What about the second black cap that is not under the cooling fan assembly. Do I drain that as well and what type and how much fluid goes back in the unit?

Thank you, ggraham. I will save this information. My searches today suggest going stronger may be more important than just pursuing a locking option.

I found a reference to updating the K46 with K57 internals. Do you have any knowledge of this?

I forgot to add the K62 is available on this tractor as an option with the large deck. The linkage could possibly be sourced from Cub Cadet.

Thanks.

Greetings. My 2018 Cub Cadet XT2 came with a K46 transmission. Due to the terrain on my property I am compelled to use tire chains even in good weather. Is there a transmission (K 62 perhaps?) with a locker option that I can swap in easily?

Hello. My husqvarna k46 is not driving. I noticed that a rear tire has bluish oil all over it. I believe an axle seal is blown and lost oil from here. Do I need to open the transmission to replace this or does it seat itself from the outside? Also I read about using 5w50 syn. Oil. Does this seem correct.

Thank you

I have a Craftsman Garden Tractor. It works fine for the last 10 seasons. It started to stop and transaxle winning before it climbed the hill but it cut grasses fine in flat area in 11st season. I removed the transaxle from the tractor today. This is the info from the transaxle:

TUFF TORQ 7A632084620 S/N: 66Y – 0002589

HOP PN: 199973

The reservoir has only small oil left in the tank. However, I have not drain the oil from the transaxle yet. There is no leak (as far as I can see from the housing. I would like to change and refill the transaxle fluid. What type of fluid it uses and how much? The reservoir has marks and show the level of fluid. However, there is no dip stick on the transaxle housing. How do I know that it is the right amount of fluid?

I will greatly appreciate any info that you can provide.

Best regards,

this Transaxle is loosing oil by spacer split how to stop it or how can i find a Transaxle

I followed your instructions for oil change and bleeding air.

I have a Husqvarna YTH24V48LS

Refilled with 10W50 synthetic oil but now it loses all drive after approx an hours operation.

Any suggestions?

I just received my new transmission and noticed it was full of oil. Do I have to drain the oil out and put new oil in or is it good to go?

My LTX1045 is leaking oil from the vent valve. I have added oil to the transmission several times and it continues to lead from the vent valve. I do have 125 hrs on it. How do I eliminate this problem?

2004 LTR180 with K46A external expansion tank. How do I check the trans oil level? Can I simply top up the oil in the expansion tank to keep the trans oil level at the correct level or or I have to add oil in the oil port under the fan?

hola tengo una husqvarna con k46 y el problema en esta es que después de 20 minutos de trabajo pierde toda la fuerza y ya cambie el aceite y el problema persiste 🙁 ¿que es lo que estara pasando?

Tuff

I have a 2007 Craftsman MTS 5500 tractor with a K46 transmission. The number on the axle appears to be 7A646084161 SN#468N806013. The transmission quit working while vaccuming leaves and going up a small grade. It has some power going on level ground but will not climb a hill. The case is clean as there are no signs of oil leaking. What should I be looking for?

How much fluid does the K46 tranny hold?

do you offer a k46 with drain plugs?for a deere L120

Thanks for sharing the information. i really enjoyed your blog article. and you’r writing a good point.

Hi Guys,

I have an L110 John Deere and had a leaking seal on the input shaft . I removed the trans-axle and brought it to my local dealer for replacement. After installing it there is no grunt in the machine. It cannot even climb a small hill. I removed it again and found the oil level a bit low so I topped it up with about a cup of suitable oil. Could this be the problem, ie. low oil? If I need to rebuild the pump assembly/motor can you supply a rebuild kit? I am in Australia and find the John Deere people here only want to sell a complete trans-axle.

i like your page but dont go far enough some these tractors work all year round so the oil spec declare what type of oil

Good evening. I own a John Deere L130 lawn tractor. Manufactured date 05/12. It doesn’t move at all. Raised rear wheels off ground tires do turn slowly,but I can stop simply by touching wheel. I understand their maybe a problem with K46 trans. What is my best option for the money to repair or replace.

I have a craftsman riding mower model 917 288561 with 150 hrs. The k46 transaxle went out and have a new one coming soon.Do i need to purge it after installing and do oil changes every 200 hrs. or so with 5w50 synthetic.I mow normal with it at home but yard has some hills and is sloped for the most part.

I just inherited an 02 John Deere LTR 180 with a tuff torq K46 transaxle. Everything is working fine but there is a little humming noise when I engage the transaxle. The article above seems to contradict itself in regards to an oil change. First paragraph says “Normally the Strider™ transaxle (K46), that is featured in many tractor & rider models, does not require any servicing for the life of the vehicle.” Then “In heavy usage applications oil changing is recommended after the 1st 50 hours of operation and every 200 hours, thereafter.” What is “heavy usage?” and should I take the transaxle out and change the fluid? Thank you so much!

I have a 11 yr. old, 400 hrs. K46 in John Deere LT160, should I remove it and change fluid and was told to use 5w50 synthetic motor oil if I do !!

-

what type oil for al,winter ,summerl year

La 165..ive drained the oil…how much is required on the refill.

How much oil is required for the transmission oil change

Hello there! This is my first visit to your blog! We are a group of volunteers and

starting a new project in a community in the same niche.

Your blog provided us beneficial information to work on. You have done

a marvellous job!

I just like the helpful info you supply on your articles.

I’ll bookmark your blog and test again right here regularly.

I’m rather certain I’ll be told plenty of new stuff right here!

Good luck for the next!

Is there an upgrade kit for the k46 transaxle? I plan on buying a Cub Cadet LT with a 42″ wide mower deck. I plan on using it to mow and pull a 15gal. trailer type sprayer. Will the K46 ever need servicing if I use it as stated? If there is an upgrade kit, what does it consist of and what is the cost?

I own the John Deere L-120 and the transmission has failed. Imagine that? Any design that requires you to have to remove the transmission to replace the fluid is pure BS. The John Deere Manual says, “The transmission is a sealed unit that requires no maintenance” To add insult to injury they want to charge me more for a replacement than the mower is worth, knowing it won’t last either? Last John Deere anything I will ever own.

hai dear,which oil using K46 gear box.(grade) .equipment using in gulf contry.

Gentelmen…good mornin…heres the prob.John Deere l 118 2006 year mod…..mower working fine…needed to replace cooling fan…so i did according to procedure…mission acomplished…hoped on mower , and now no forward or reverse…replaced drive belt and drive idler ,and tension pulley asembley….no change…Now i did jack up and purge system and got slight movement but no torque…pullin my hair out in Texas…!!!!!!

I am having problems with my John Deere L130 tractor transmission slipping. Belt and pulleys are new. My tractor is a 2004 and is in very good condition. If I remove the transmission and change the oil can I drain most of the old oil from the top plug. I have observed someone trying to suck out the oil but he only got about a pint out. I may end up rebuilding or replacing the transmission but I would like to try oil first . If I have to replace the transmission should I upgrade to a k66 or another k46. If I have to replace the transmission I will contact you for what transmission will fit my tractor.

Leave a Reply